Lever Simple Machine- Introduction, Types, And Applications

Lever simple machine has been used for thousands of years to make work easier. From ancient civilizations to modern-day technology. Levers have played a vital role in shaping the world we live in. In this article, we will explore the fascinating world of levers, understand what they are, how they work, and their different types.

What is a Lever Simple Machine?

Levers are simple machines that are designed to make work easier by multiplying force or changing the direction of a force. They have been used for thousands of years, and their importance cannot be overstated. From the simplest tool to the most complex machinery, levers have played a crucial role in human civilization.

A lever is a simple machine that consists of a rigid object (a bar or plank) and a fulcrum (a fixed point on the object). Levers are used to transmit force around a pivot point, allowing for the application of force over a greater distance than would be possible by using the force directly.

The components of a lever

A lever is a simple machine that consists of three main components: the fulcrum, the load, and the force. These components work together to allow the lever to lift heavy objects with less effort.

Fulcrum

The fulcrum is the fixed point around which the lever rotates. It is the point at which the lever is supported and balanced. In order for the lever to work, the fulcrum must be positioned correctly. The position of the fulcrum determines the amount of force needed to lift the load.

Load

The load is the object that is being lifted or moved by the lever. It is the weight or resistance that the lever is designed to overcome. The load can be any object that needs to be lifted, such as a heavy rock or a piece of machinery.

Force

The force is the effort that is applied to the lever to lift the load. It is the energy that is used to overcome the weight or resistance of the load. The force can be applied in various ways, such as by pushing down on one end of the lever or by pulling up on the other end of the lever.

In addition to these three components, levers also have two arms: the input arm and the output arm. The input arm is the distance between the force and the fulcrum, while the output arm is the distance between the load and the fulcrum. The ratio of these two arms determines the mechanical advantage of the lever.

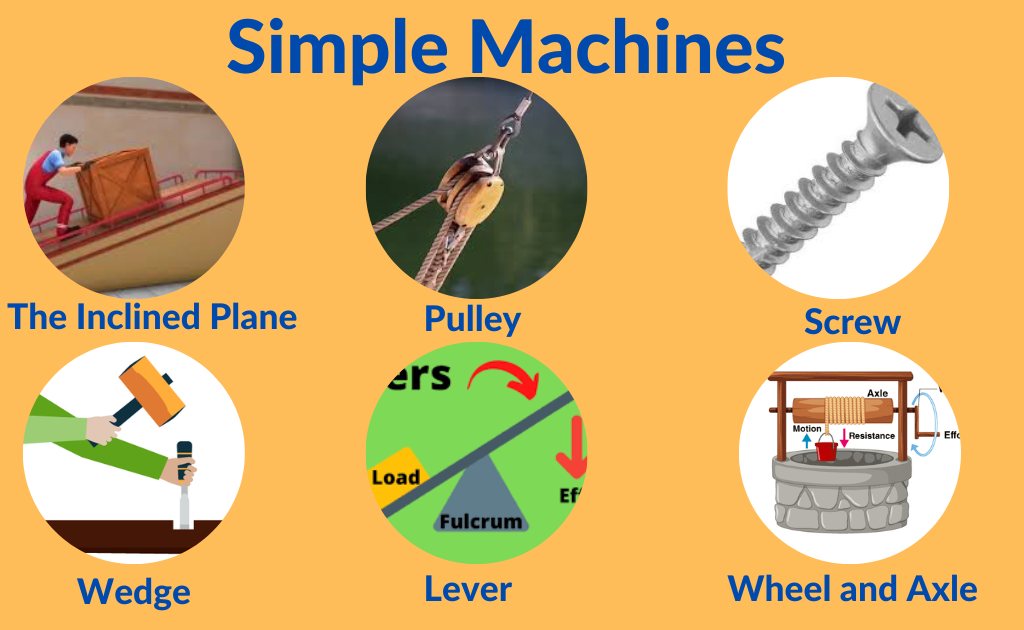

Types of levers

There are three types of levers: first-class levers, second-class levers, and third-class levers. The classification of levers is based on the location of the fulcrum, the input force, and the output force.

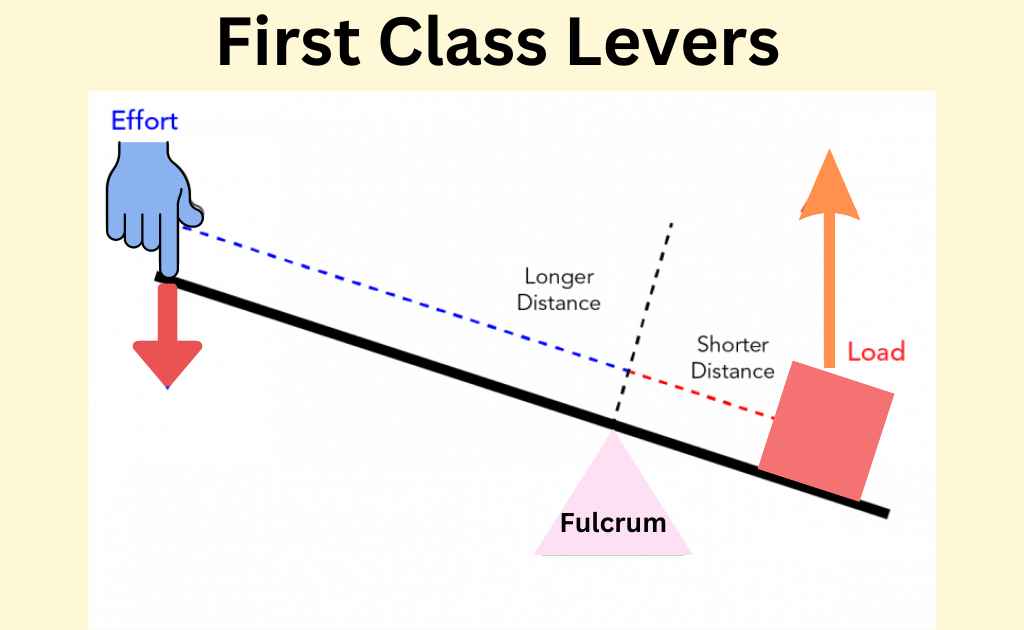

First-class levers

In a first-class lever, the fulcrum is located between the input force and the output force. This means that the input force and the output force are on opposite sides of the fulcrum. Examples of first-class levers include seesaws, scissors, and pliers.

Second-class levers

In a second-class lever, the output force is located between the fulcrum and the input force. This means that the input force and the output force are on the same side of the fulcrum. Examples of second-class levers include wheelbarrows, nutcrackers, and bottle openers.

Third-class levers

In a third-class lever, the input force is located between the fulcrum and the output force. This means that the input force and the output force are on the same side of the fulcrum, but the input force is closer to the fulcrum. Examples of third-class levers include tweezers, shovels, and fishing rods.

The principle of moments

The principle of moments of levers is a fundamental concept in the study of levers. According to this principle, the product of the force applied to a lever and its distance from the fulcrum is equal to the product of the load being lifted and its distance from the fulcrum. This principle is also known as the law of the lever.

In simpler terms, the principle of moments of lever states that the force applied to a lever must be balanced by the force of the load being lifted. The distance from the fulcrum at which the force is applied, as well as the distance from the fulcrum at which the load is placed, determine the mechanical advantage of the lever.

For example, if a load of 100 pounds is placed on a lever 10 feet away from the fulcrum, and a force of 50 pounds is applied to the lever 20 feet away from the fulcrum, the lever will be balanced. This is because the force applied to the lever (50 pounds) multiplied by its distance from the fulcrum (20 feet) is equal to the load being lifted (100 pounds) multiplied by its distance from the fulcrum (10 feet).

The principle of moments of levers is important because it allows us to understand how levers work and how they can be used to lift heavy loads with less effort. By adjusting the distances between the force and the load, we can change the mechanical advantage of the lever and make it easier to lift heavy objects.

Real-life applications of levers

Levers are simple machines that are used in many real-life applications. They are commonly used to lift heavy loads with less effort, as well as to move and position objects. Here are some examples of real-life applications of levers:

Crowbars: Crowbars are levers that are used to pry open doors or lift heavy objects. They consist of a long, straight bar with a curved end that is used as a fulcrum. The force is applied to one end of the bar, while the load is lifted using the other end.

Seesaws: Seesaws are playground equipment that consists of a long, narrow board balanced on a fulcrum. When one person pushes down on one end of the board, the other end rises, allowing the other person to be lifted up in the air.

Wheelbarrows: Wheelbarrows are gardening tools that consist of a long handle, a wheel, and a tray for carrying soil or other materials. The wheel acts as a fulcrum, allowing the user to lift and move heavy loads with less effort.

Scissors: Scissors are levers that are used to cut paper, fabric, and other materials. They consist of two arms that pivot around a fulcrum, with the force being applied to the handles and the load being cut by the blades.

Bottle openers: Bottle openers are levers that are used to remove caps from bottles. They consist of a curved end that acts as a fulcrum, with the force being applied to the other end to lift the cap off the bottle.

Car jacks: Car jacks are tools used to lift cars off the ground for repairs or maintenance. They consist of a long handle and a lifting pad that acts as a fulcrum, allowing the user to lift the car with less effort.

Fishing rods: Fishing rods are levers that are used to catch fish. The rod acts as a lever, with the force being applied to the handle and the load being the weight of the fish on the other end of the line.

The advantages of levers

Levers are simple machines that can provide a number of advantages when used correctly.

Mechanical advantage:

One of the main advantages of using a lever simple machine is that it can provide a mechanical advantage, allowing a person to lift a heavy load with less effort. This is especially useful in situations where a heavy load needs to be lifted, such as when using a car jack to change a tire.

Precision:

Lever simple machine can also provide a high degree of precision, allowing the user to make small adjustments to the position of an object. This is useful in situations where precision is important, such as when using a fishing rod to catch a fish.

Increased speed:

Lever simple machine can also be used to increase the speed at which an object is moved or lifted. This is useful in situations where time is of the essence, such as when using a wheelbarrow to move a heavy load quickly.

Disadvantages of Lever

The lever simple machine can also have some disadvantages that need to be considered. Here are some disadvantages of the lever simple machine.

Limited range of motion:

One of the main disadvantages of using a lever simple machine is that it has a limited range of motion. This means that it can only be used to lift or move objects within a certain range of motion, and may not be suitable for all types of objects.

Inefficient for some tasks:

Levers may also be inefficient for some tasks, such as lifting objects that are too heavy for a single person to lift, or moving objects that are too large or bulky.

Requires skill:

Finally, using a lever simple machine effectively requires skill and experience. Improper use of a lever can lead to injury or damage to the object being lifted or moved.

Related FAQs

What is a lever simple machine?

A lever simple machine that consists of a rigid object and a fulcrum. Levers are used to transmit force around a pivot point, allowing for the application of force over a greater distance than would be possible by using the force directly.

What is the mechanical advantage of a lever simple machine?

The mechanical advantage of a lever simple machine is the ratio of the output force to the input force. The longer the lever arm, the greater the mechanical advantage.

What is the impact of levers on our daily lives?

Levers have had a significant impact on our daily lives, from simple tools to complex machinery. The ability to move heavy objects, change the direction of forces, and transmit forces over a greater distance has made our lives easier and more productive.

written by

written by

Leave a Reply