Vernier Caliper-Definition, Working, And Parts

A Vernier caliper is a precise measuring instrument used for measuring the distance between two opposite sides of an object. It is typically used in industrial, mechanical, and engineering applications where accuracy and precision are critical.

What is a Vernier Caliper?

The Vernier caliper owes its name to Pierre Vernier, a French mathematician and instrument maker who invented the Vernier scale in 1631. His innovative design revolutionized precise measurements, enabling the calculation of finer fractions than previously possible.

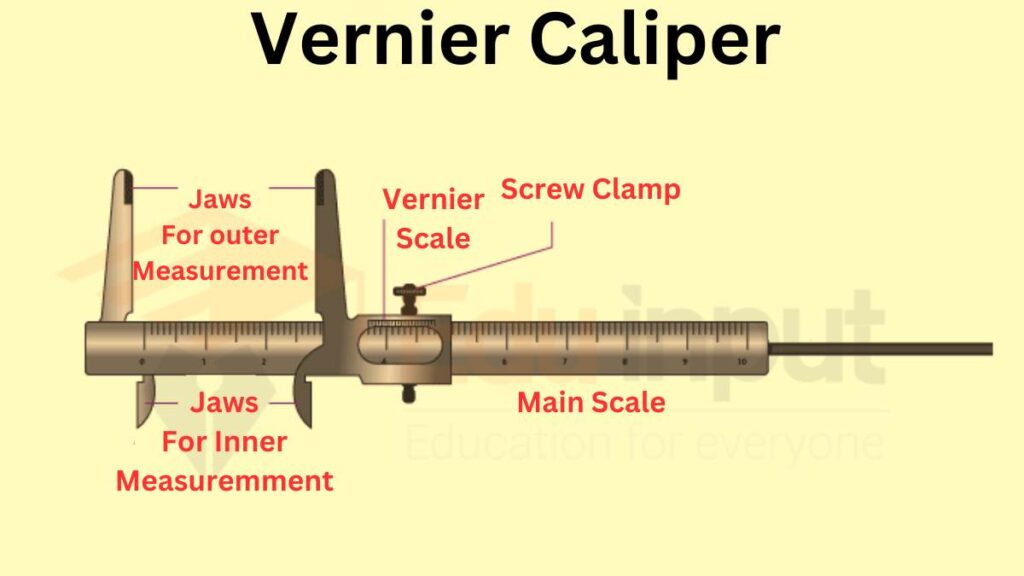

A Vernier caliper is a handheld measuring device used to gauge the dimensions of an object with remarkable accuracy. It consists of a main scale, a sliding Vernier scale, and a pair of jaws or measuring surfaces. The main scale is typically graduated in millimeters, while the Vernier scale provides additional decimal place readings, enhancing the precision of measurements.

Parts of a Vernier Caliper

These are some key parts of the vernier caliper.

- Main Scale: The main scale is the primary measuring scale on a Vernier caliper, usually graduated in millimeters or inches. It extends along the fixed jaw and provides the whole number part of the measurement.

- Vernier Scale: The Vernier scale is a secondary measuring scale that slides alongside the main scale. It consists of multiple divisions, which are slightly smaller than the corresponding divisions on the main scale. The Vernier scale allows for precise measurement of fractions or decimal parts of a unit.

- Jaws: The jaws of a Vernier caliper are responsible for holding the object being measured. The fixed jaw is located at one end of the main scale, while the movable jaw is attached to the Vernier scale. These jaws ensure accurate and stable positioning of the object.

- Depth Gauge: Some Vernier calipers feature a depth gauge, which extends from the back of the fixed jaw. This additional attachment allows for measuring depths or step dimensions.

Working of Vernier Caliper

The working principle of a Vernier caliper relies on the alignment of the main and Vernier scales. When measuring an object the jaws are positioned on either side and the Vernier scale is aligned with the main scale. The user then reads the measurement from the Vernier scale combining it with the corresponding whole number from the main scale.

The Vernier scale’s divisions are spaced slightly differently than those on the main scale, creating a Vernier constant. This constant determines the precision of the Vernier caliper. The Vernier constant allows for precise readings beyond the resolution of the main scale by aligning the scales.

Types of Vernier Calipers

Vernier calipers come in various types, each catering to specific measurement requirements. The most common types include:

- Standard Vernier Caliper: This traditional Vernier caliper consists of a main scale and a Vernier scale, providing measurement readings with high accuracy.

- Dial Vernier Caliper: In this type, the Vernier scale is replaced by a dial indicator, enabling direct readings without requiring manual alignment.

- Digital Vernier Caliper: A digital Vernier caliper features an electronic display that shows precise measurements. This type is easy to read and eliminates potential human errors in reading analog scales.

- Depth Vernier Caliper: This variation includes an additional depth gauge to measure the depth of holes or recesses accurately.

How to Use the Vernier Caliper?

Follow these steps to obtain accurate measurements using a Vernier caliper.

- Zero Positioning: Close the jaws and ensure that the Vernier scale aligns perfectly with the zero mark on the main scale. This step sets the instrument to the zero reading.

- Select Measurement Mode: Depending on the desired unit of measurement (millimeters or inches), adjust the Vernier caliper accordingly.

- Object Placement: Place the object to be measured between the jaws, ensuring it rests against both measuring surfaces. Avoid applying excessive force to prevent distortion.

- Read the Measurement: Observe the position of the Vernier scale division that aligns precisely with any division on the main scale. Record the whole number from the main scale and the decimal reading from the Vernier scale.

- Consider the Vernier Constant: For more precise readings, check if there is a Vernier constant by observing which division on the Vernier scale aligns with a division on the main scale. Add this constant to the Vernier scale reading.

Benefits of Using a Vernier Caliper

Using a Vernier caliper offers several advantages. It reduces the error in measurement.

- High Precision: Vernier calipers provide accurate measurements with greater precision than traditional rulers or tape measures.

- Versatility: These calipers are suitable for measuring various objects, including diameters, depths, and lengths.

- Ease of Use: Once familiar with the instrument, taking precise measurements becomes straightforward.

- Portable: Vernier calipers are compact and portable, making them convenient for on-the-go measurements.

Common Applications of Vernier Calipers

Vernier calipers find applications in numerous fields.

- Engineering: Engineers utilize Vernier calipers for precise measurements during design, prototyping, and manufacturing processes.

- Machining: Machinists rely on Vernier calipers to ensure accurate dimensions in metalworking, carpentry, or other machining tasks.

- Quality Control: Vernier calipers play a crucial role in quality control, helping to verify product dimensions and specifications.

- Education: In educational settings, Vernier calipers are used to teach measurement principles and techniques to students.

Maintenance and Care

To keep your Vernier caliper in optimal condition, consider the following maintenance tips:

- Cleanliness: Regularly wipe the measuring surfaces and jaws with a clean cloth to remove dust or debris.

- Storage: Store your Vernier caliper in a protective case or pouch to prevent damage and ensure accuracy.

- Avoid Excessive Force: Handle the caliper gently, avoiding excessive force that could damage the measuring surfaces or jaws.

- Calibration: Periodically calibrate your Vernier caliper to ensure accuracy. Professional calibration services are available for precision instruments.

Tips for Accurate Measurements

To achieve accurate measurements with a Vernier caliper, keep the following tips in mind:

- Proper Positioning: Ensure the object is placed securely between the jaws, without any slippage or misalignment.

- Read at Eye Level: Align your line of sight with the scale markings to minimize parallax errors.

- Take Multiple Measurements: Repeat measurements to ensure consistency and identify any potential errors.

- Account for Temperature: Extreme temperatures can affect the accuracy of metal Vernier calipers. Allow them to adjust to the ambient temperature before use.

Related FAQs

What is a vernier caliper used for?

A vernier caliper is used for precise measurement of lengths, diameters, and depths with high accuracy.

What is a vernier caliper and its principle?

A vernier caliper is a measuring tool that consists of a main scale and a sliding Vernier scale. The principle behind its operation is aligning the Vernier scale with the main scale to obtain precise measurements by reading both scales.

How do you read a vernier?

To read a vernier caliper, align the zero mark of the Vernier scale with the main scale and observe which division on the Vernier scale aligns perfectly with a division on the main scale. This aligned division provides the decimal part of the measurement, while the corresponding whole number from the main scale gives the complete measurement.

written by

written by

Leave a Reply