What is Material Failure?-Definition, Types, And Failure of Brittle Materials

Material Failure is defined as any type of damage to a solid material caused by an external force.

What is Material Failure?

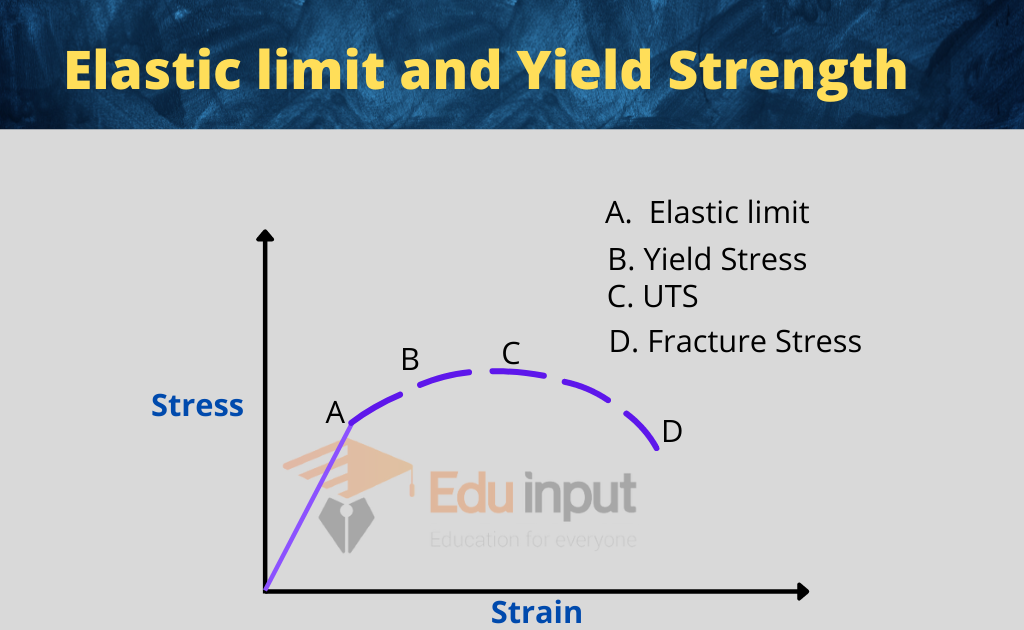

The field of materials science and solid mechanics tries to predict the conditions under which solid materials fail under the action of external loads. The failure of a material is usually classified as brittle failure or ductile failure.

Depending on the conditions (such as temperature, state of stress, loading rate) most materials can fail in a brittle or ductile manner or both. For most practical situations, a material can be classified as either brittle or ductile.

Material failure is the loss of load carrying capacity of a material unit in materials science. Material failure can be examined on many different scales, from the smallest to the largest. Material failure is important for the determination of the integrity of the structure in structural problems, where the structural response may be beyond the initiation of nonlinear material behavior.

The determination of the structure’s damage, due to material failure, is still under intensive research because of the lack of globally accepted fracture criteria.

Types of material failure

Material failure is categorized into two parts

- Microscopic material failure

- Macroscopic material failure

Microscopic material failure

Microscopic material failure can be defined in terms of crack initiation and propagation. It is useful for gaining insight into the cracking of simple structures under well-defined global load distributions with the use of such methodologies. Microscopic failure takes into account the initiation and propagation of a crack.

The failure criteria, in this case, are related to the broken bone. Micromechanical failure models combine the advantages of continuum mechanics and classical fracture mechanics, and they are some of the most popular failure models in this area.

The model that was proposed by Gurson and extended by Tvergaard and Needleman is known as GTN. Rousselier has proposed a new approach that is based on continuum damage mechanics and thermodynamics. Both models form a modification of the von Mises yield potential by introducing a scalar damage quantity, which represents the void volume fraction of the cavities.

Macroscopic failure

Load carrying capacity and energy storage capacity are equivalently defined as macroscopic material failure. There are four categories of macroscopic failure criteria.

- Stress or strain failure

- Energy type failure

- Damage failure

- Empirical failure

Failure of brittle materials

It is possible to determine the failure of brittle materials using several approaches.

- Phenomenological failure criteria

- Linear elastic fracture mechanics

- Elastic-plastic fracture mechanics

- Energy-based methods

- Cohesive zone methods

Leave a Reply