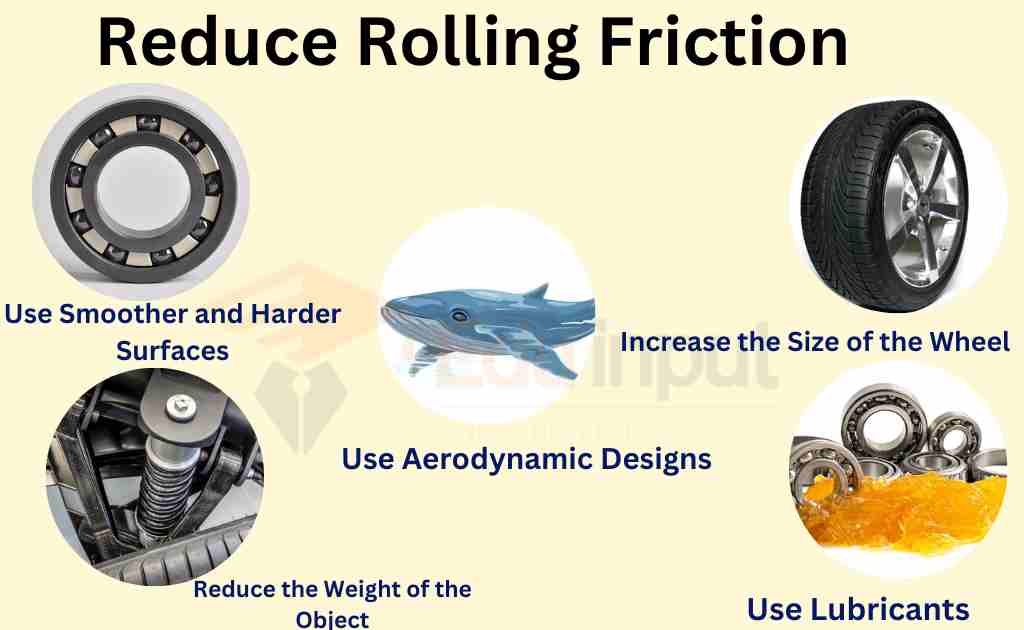

How to reduce rolling friction?

Rolling friction can be reduced by changing factors such as the surface material, the weight of the object, the size of the wheel, using lubricants, and using aerodynamic designs. By understanding how these factors affect rolling friction, you can design machines and vehicles that are more efficient and use less energy.

How to reduce rolling friction?

Reducing rolling friction is important for improving the efficiency of machines and vehicles that rely on rolling motion. Here are some ways to reduce rolling friction:

1. Use Smoother and Harder Surfaces

Smoother and harder surfaces have lower coefficients of rolling friction, which can reduce rolling friction. For example, using ceramic bearings instead of steel bearings in a bicycle can reduce rolling friction and improve speed.

2. Reduce the Weight of the Object

As mentioned earlier, rolling friction is directly proportional to the weight of the object. This means that reducing the weight of the object can reduce the force of rolling friction. For example, using lightweight materials like carbon fiber in a car can reduce rolling friction and improve fuel efficiency.

3. Increase the Size of the Wheel

Rolling friction is inversely proportional to the size of the wheel. This means that increasing the size of the wheel can reduce the force of rolling friction. For example, using larger wheels on a cart can reduce rolling friction and make it easier to push or pull.

4. Use Lubricants

Lubricants can reduce the friction between two surfaces in contact, which can reduce rolling friction. For example, using grease or oil on the axles of a car can reduce rolling friction and improve fuel efficiency.

5. Use Aerodynamic Designs

Aerodynamic designs can reduce air resistance, which can reduce rolling friction. For example, using a streamlined body design in a car can reduce air resistance and improve fuel efficiency.

Leave a Reply