Chemical Spill Response Procedure-Step by step guide

Effective management of chemical spills is a critical aspect of safety in environments where chemicals are present. This comprehensive guide outlines a systematic approach to managing chemical spills, ensuring a swift, safe, and efficient response.

Initial Response Protocol

- Identify the Hazard: Rapidly assess the type and quantity of the spilled chemical. Immediately refer to the Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) for detailed information on the chemical’s hazards and recommended handling procedures.

- Secure the Area: Alert people in the vicinity and evacuate the area if necessary. Establish a safety perimeter based on the nature and extent of the spill.

- Containment Strategies: Utilize appropriate spill containment methods such as absorbent materials, spill berms, or dikes to prevent the spread of the chemical.

- Ensure Adequate Ventilation: Open windows and use ventilation systems to dissipate any harmful vapors, especially in confined spaces.

- Personal Protective Equipment (PPE): Equip yourself with suitable PPE, including gloves, safety goggles, respirators, and protective clothing, depending on the chemical’s nature.

Detailed Clean-up Procedure

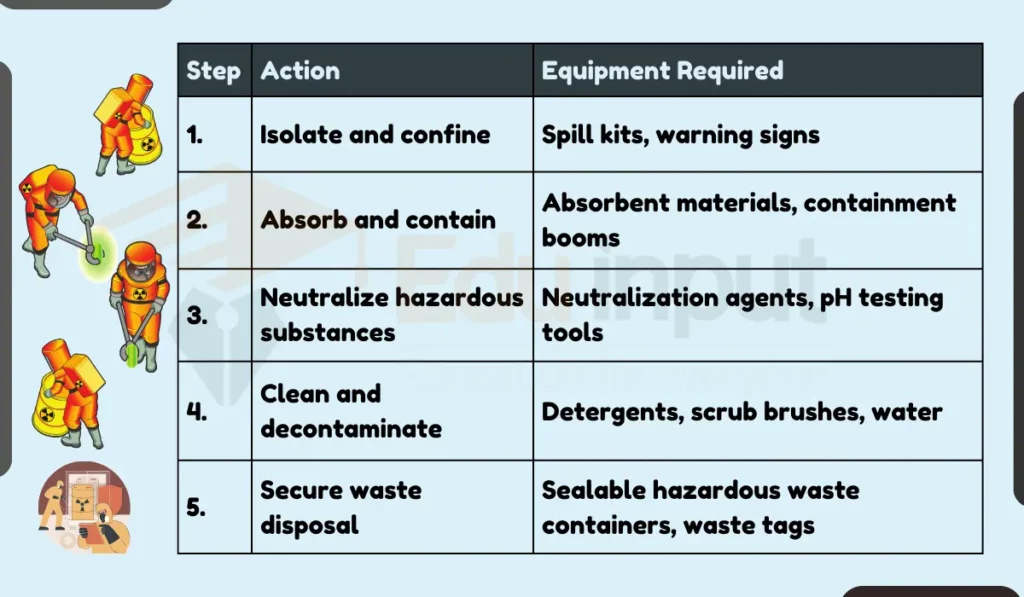

| Step | Action | Equipment Required |

|---|---|---|

| 1. | Isolate and confine | Spill kits, warning signs |

| 2. | Absorb and contain | Absorbent materials, containment booms |

| 3. | Neutralize hazardous substances | Neutralization agents, pH testing tools |

| 4. | Clean and decontaminate | Detergents, scrub brushes, water |

| 5. | Secure waste disposal | Sealable hazardous waste containers, waste tags |

Reporting and Documentation

- Incident Reporting: Immediately notify facility management, safety officers, or relevant authorities. Be clear about the spill’s location, type, and size.

- Documentation: Meticulously document the incident, including the time of occurrence, types of chemicals involved, estimated quantities, response actions taken, and any injuries or property damage.

Post-Incident Follow-up

- Restock and Inspect: After clean-up, inspect and replenish spill response materials and equipment.

- Debrief and Review: Conduct a thorough review of the incident to identify lessons learned and opportunities for improving spill response procedures.

Training and Preparedness

- Regular Training: Conduct periodic training sessions for staff on chemical handling, spill response techniques, and emergency procedures.

- Mock Drills: Implement mock spill scenarios to enhance preparedness and response efficiency.

Statistics and Reference

In 2023, the [U.S. Bureau of Labor Statistics] reported that chemical spills were among the top five causes of workplace injuries in industrial and laboratory settings. The report emphasizes the criticality of rapid response and effective spill management protocols in mitigating risks.

- Reference: U.S. Bureau of Labor Statistics, “Annual Report on Workplace Safety: Focus on Chemical Spills” (2023).

It’s important to customize these guidelines to fit the specific needs of your facility, considering the types of chemicals handled, facility layout, and available resources. A well-prepared response to chemical spills is key to maintaining a safe work environment.

Leave a Reply