Graduated Cylinder-Parts, Sizes, Types, and Applications

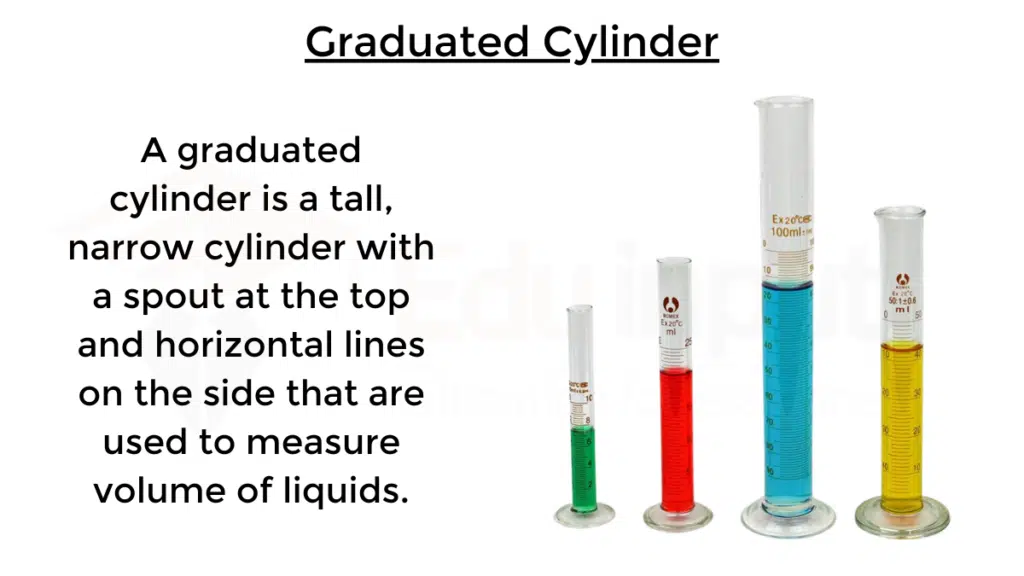

What is a Graduated Cylinder?

A graduated cylinder is a measuring cylinder. It is a narrow cylindrical container that is used to accurately measure out volumes of liquid. Graduated cylinders are made of glass or clear plastic and have printed increments marking the volume scale along their length.

Parts of Graduated Cylinder

The main parts of a graduated cylinder are:

1. Cylindrical barrel

The cylindrical barrel is the main part of the graduated cylinder and is where the liquid is held. It is typically made of glass or plastic, and is clear so that the liquid level can be easily seen. The barrel is usually taller than it is wide, in order to increase the accuracy of volume measurements.

2. Pouring lip

The pouring lip is a spout at the top of the barrel that allows the liquid to be poured out easily and accurately. Pouring lips are especially useful when transferring liquids between containers.

3. Base

The base is the bottom of the graduated cylinder and provides stability. It may be flat or rounded, depending on the type of graduated cylinder. Rounded bases are less likely to tip over, but they can make it more difficult to read the graduations.

4. Graduations

The graduations are volumetric markings on the barrel of the graduated cylinder that indicate the volume of liquid in the cylinder. Graduations are typically in milliliters (mL) or liters (L). The graduations should be evenly spaced and easy to read.

5. Stopper

Some graduated cylinders have a stopper that can be inserted into the top of the barrel to seal the cylinder. This is useful for preventing liquids from spilling or evaporating. Stoppers are typically made of glass or rubber.

Sizes of Graduated Cylinders

Graduated cylinders come in a wide range of sizes to accommodate different volume needs:

- Small volumes (~1-10 mL) are used for precise measurements and titrations. These have graduations every 0.1 mL.

- Medium sizes (~50-250 mL) are common for general lab work. These have graduations every 1 mL.

- Large volumes (500 mL – 2000 mL) are used when measuring out large quantities of liquids. These have graduations every 10 mL.

Selecting the right size cylinder allows for an appropriate level of precision for the desired volume. Using a cylinder with a capacity far greater than the volume needed will reduce accuracy.

Types of Graduated Cylinders

There are 4 main types of graduated cylinders based on their shape:

1. Standard cylindrical graduated cylinder

This is the most common type of graduated cylinder. It has straight sides with a flat or rounded bottom and is made of glass or clear plastic.

The volumetric graduations are printed along the full length of the cylinder. Standard graduated cylinders are available in a variety of sizes, from 1 mL to 2000 mL capacity. They are used for basic volume measurements and liquid transfers.

2. Buret-type graduated cylinder

Buret-type graduated cylinders have a tapered cylindrical shape with a stopcock valve at the bottom. This allows for precise dispensing by controlling the flow of liquid.

Buret-type graduated cylinders often have a reading magnification lens in the stopcock to make it easier to read the graduations. They are useful for accurately dispensing small amounts of liquids in titrations and other quantitative analyses.

3. Erlenmeyer or conical graduated cylinder

Erlenmeyer or conical graduated cylinders have a cylinder shape with a conical bottom section. This provides the ability to mix or swirl liquid. The graduations may only extend partway down the cone, so these cylinders are not suitable for precise volume measurements.

They are better suited for general mixing, stirring, or titrations. Erlenmeyer graduated cylinders are sturdier than standard cylinders due to their wide base.

4. Centrifuge graduated tube

Centrifuge graduated tubes are rimmed centrifuge tubes with graduated markings. This allows for measuring the volume of liquid after it has been spun and separated in a centrifuge. Centrifuge graduated tubes are typically made of thick clear plastic to withstand the high g-forces generated by centrifuges.

They are limited to smaller volumes suitable for centrifuges, and the graduations may not be as precise as glass cylinders.

How to use a Graduated Cylinder?

Using a graduated cylinder takes some practice to master the technique. Follow these steps for proper usage:

- Select a clean, dry graduated cylinder with an appropriate size for your volume needs.

- Place the cylinder on a flat, level surface. Read the meniscus at eye level to avoid parallax errors.

- Slowly pour the liquid into the cylinder, being careful not to spill. The liquid should be filled to just below the desired volume mark.

- Wait for the liquid to settle and come to a complete stop. Read the bottom of the meniscus – the lowest point where the liquid surface meets the glass.

- Record the measurement to the proper number of significant figures based on the cylinder’s resolution.

- Common errors include reading the meniscus incorrectly, reading at the wrong angle, and allowing liquid to stick to the sides of the cylinder. Take care to avoid these.

Measurement

To read a graduated cylinder accurately, you should hold the cylinder at eye level and read the bottom of the meniscus. The meniscus is the curved surface of the liquid at the top of the cylinder. It is caused by the attraction of the liquid molecules to the walls of the cylinder.

To calculate the error of a graduated cylinder reading, you need to know the least count of the cylinder. The least count is the smallest division on the graduated scale. For example, a graduated cylinder with a least count of 0.1 mL will have errors of ±0.1 mL.

Here are some examples of how to report the results of a graduated cylinder measurement, taking into account the error:

- Reading: 36.5 mL

- Report: 36.5 ± 0.1 mL

- Reading: 40.0 mL

- Report: 40.0 ± 0.1 mL

Experiments Using Graduated Cylinders

Graduated cylinders are employed in many common laboratory experiments:

- Preparing chemical solutions by measuring out solvent and solute amounts to achieve a target concentration.

- Performing serial dilutions by transferring measured volumes of a solution into new measured volumes of diluent.

- Finding the density of an unknown liquid by weighing a known volume.

- Measuring the volume of a gas sample by displacing water in an inverted cylinder.

- Monitoring a chemical reaction by observing volume changes over time.

- Calibrating other glassware by delivering a measured volume.

Uses of Graduated Cylinders

Graduated cylinders are used for:

- Measuring out specific amounts of liquids for reactions and experiments.

- Preparing solutions by mixing measured amounts of solvent and solute.

- Performing titrations to determine unknown concentrations.

- Determining the density of liquids based on a volume measurement.

- Measuring volumes for dilutions by mixing known concentrations.

- Calibrating other instruments such as pipettes by delivering a known volume.

Leave a Reply