How Do X-Rays Penetrate A Sheet Of Steel?

X-rays are able to penetrate a sheet of steel due to their wavelength and energy. X-rays have shorter wavelengths and higher energy compared to visible light. When X-rays pass through a material, such as steel, they can interact with the material’s atomic structure.

This interaction causes the X-rays to be absorbed or scattered, allowing them to pass through the steel. X-rays’ ability to penetrate materials depends on the material’s thickness and density. Thinner and less dense materials, like steel, allow more X-rays to pass through.

What are X-Rays?

X-rays are a form of electromagnetic radiation, similar to visible light but possessing much higher energy. Discovered by Wilhelm Roentgen in 1895, X-rays have since become an indispensable tool in various fields, from medical diagnostics to materials testing.

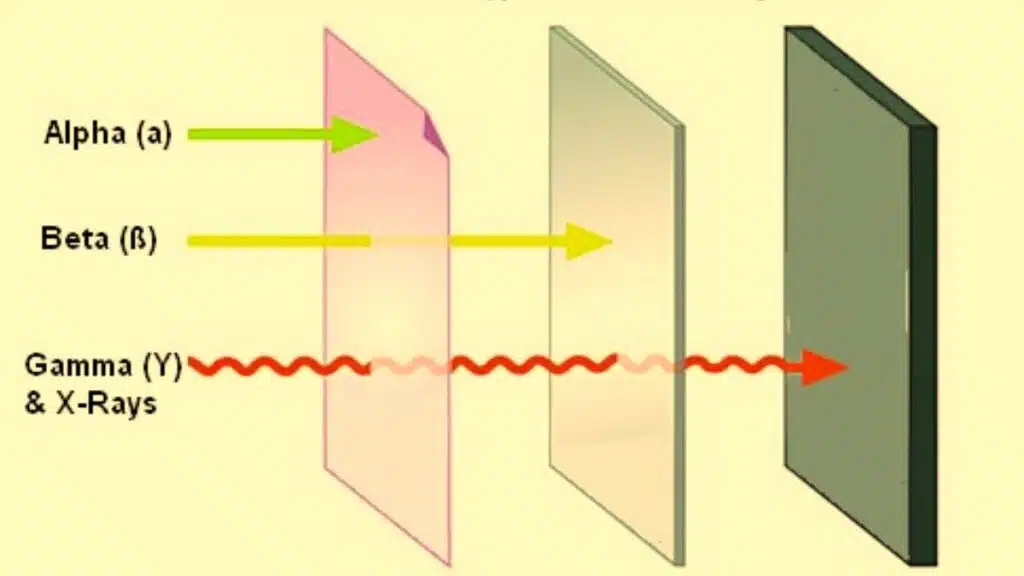

The Nature of Penetration

X-rays have a unique ability to penetrate solid objects due to their high energy levels. This penetration occurs because X-rays possess shorter wavelengths compared to visible light. These shorter wavelengths enable them to pass through the gaps between atoms and molecules in materials, including steel.

Interaction with Matter

X-rays interact with matter through two primary processes: scattering and absorption. When X-rays encounter matter, they may undergo scattering, where they change direction but still continue to travel through the material. On the other hand, absorption occurs when X-rays are absorbed by the material, reducing their intensity.

X-Rays and Steel Penetration

The Challenge of Steel

Steel is known for its strength and density, making it a challenging material for many types of radiation to penetrate. However, X-rays are exceptionally suited to this task due to their high energy levels.

The Role of Thickness

The ability of X-rays to penetrate a sheet of steel depends on its thickness. Thinner sheets allow X-rays to pass through with relative ease, while thicker sheets may absorb or scatter the X-rays, reducing their penetration capabilities.

The Importance of X-Ray Penetration in Industry

Non-Destructive Testing (NDT)

X-ray penetration through steel has revolutionized the field of non-destructive testing. Industries, such as aerospace and manufacturing, use X-rays to inspect the integrity of steel components without causing any damage. This helps detect defects, cracks, or other structural issues that might be hidden beneath the surface.

Quality Control

In manufacturing, ensuring the quality of steel products is of utmost importance. X-rays aid in quality control by allowing inspectors to examine the interior of a steel piece for any imperfections, ensuring that only products meeting strict standards are delivered to consumers.

Advancements in X-Ray Technology

Digital Radiography

Advancements in X-ray technology have led to the development of digital radiography. This technique replaces traditional film-based X-rays with digital sensors, allowing for quicker imaging and more precise analysis.

Computerized Tomography (CT)

CT scans, commonly used in medical diagnostics, have also found applications in materials testing. By taking a series of X-ray images from different angles, a three-dimensional image of the object’s interior can be reconstructed. This provides even more detailed information about the material’s structure.

Leave a Reply