Separatory Funnel-Principle, Parts, Types, Sizes, and Applications

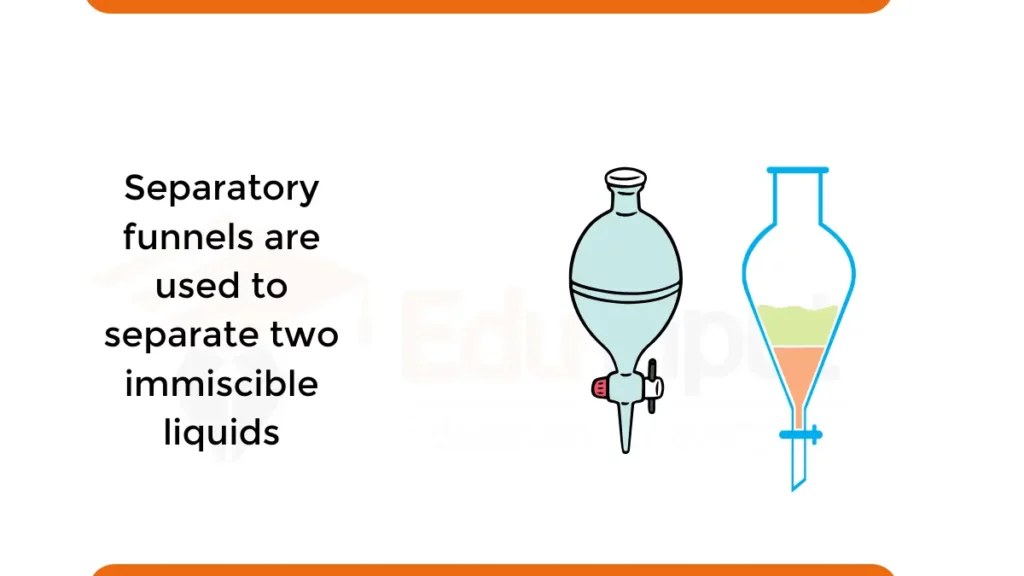

What is Separatory Funnel?

A separatory funnel, also known as a separation funnel, is a piece of laboratory glassware used to separate two immiscible liquids. It consists of a conical or pear-shaped vessel with a stopcock at the bottom. The stopcock allows the liquids to be drained off separately from the funnel.

Principle of Separatory Funnel

The separatory funnel works on the principle that immiscible liquids can be separated based on the difference in their densities. The denser liquid sinks to the bottom while the lighter liquid floats on top. This allows the two liquids to be drained out separately from the stopcock. The separating funnel allows clear and efficient separation of liquids that do not mix.

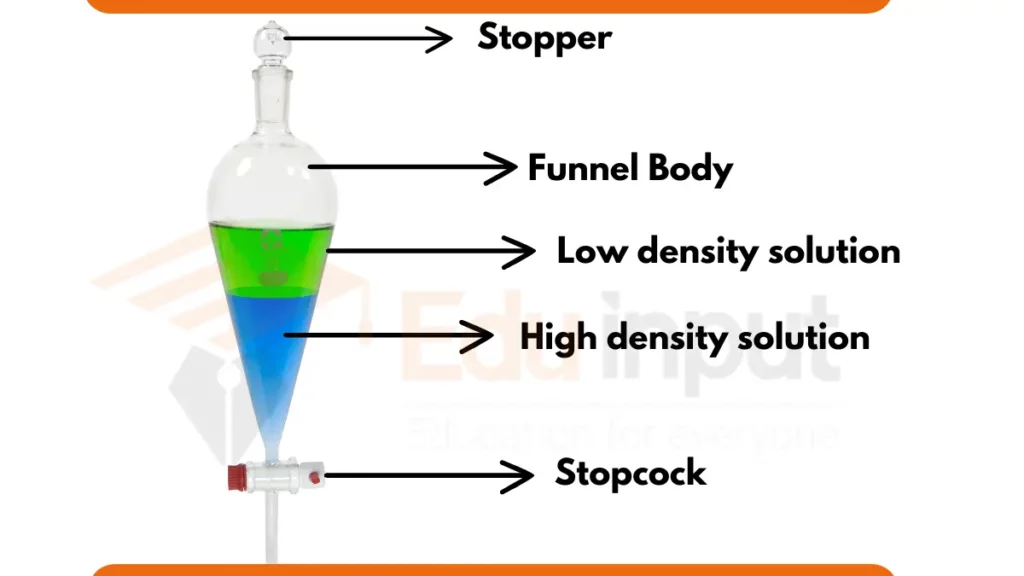

Parts of Separatory Funnel

Here are the main parts of separatory funnel:

1. Funnel body

The funnel body is the main part of the separatory funnel and is where the liquids to be separated are held. It is typically made of borosilicate glass, which is resistant to heat and chemical attack.

The funnel body is usually pear-shaped or cylindrical, with a wider top than bottom. The wider top allows for easy pouring of liquids into the funnel, while the narrower bottom helps to minimize the interface between the two layers of liquid.

2. Stopcock

The stopcock is a valve that controls the flow of liquids from the separatory funnel. It is typically made of glass or PTFE and has a tapered plug that can be rotated to open or close the valve.

The stopcock has a keyhole-shaped opening that allows the liquid to flow out of the funnel when the valve is open. The stopcock key is a small piece of Teflon or glass that fits into the keyhole-shaped opening and helps to prevent leaking.

3. Stopper

The stopper is a cap that closes the top opening of the separatory funnel when it is not in use. It is typically made of cork or glass and has a tapered shape that fits snugly into the top of the funnel. The stopper prevents liquids from evaporating or spilling out of the funnel.

4. Stand/Clamp

The stand and clamp are used to hold the separatory funnel in place during the separation process. The stand is a vertical support that holds the funnel, while the clamp is a device that attaches to the stand and secures the funnel in place.

The stand and clamp are essential for preventing the funnel from tipping over or moving during the separation process.

Types

There are four main types of separatory funnel based on their shape and functionality:

1. Pear-shaped separatory funnel

The pear-shaped separatory funnel is the most common type of separatory funnel. It has a pear-shaped body with a wider top than bottom. The wider top allows for easy pouring of liquids into the funnel, while the narrower bottom helps to minimize the interface between the two layers of liquid.

Pear-shaped separatory funnels are typically made of borosilicate glass and are available in a variety of sizes, from 60 mL to 2000 mL.

2. Cylindrical separatory funnel

The cylindrical separatory funnel has a cylindrical body with straight sides. This allows for easy visibility of the liquid layers, which can be helpful when separating two liquids that are close in density.

Cylindrical separatory funnels are typically made of borosilicate glass and are available in a variety of sizes, from 60 mL to 1000 mL.

3. Micro separatory funnel

Micro separatory funnels are smaller than standard separatory funnels and have capacities less than 50 mL. They are used for small-scale separations, such as those that are performed in analytical chemistry.

Micro separatory funnels are typically made of borosilicate glass or PTFE and are available in a variety of sizes, from 10 mL to 50 mL.

4. Automatic separatory funnel

Automatic separatory funnels are motorized funnels that automate the separation process. They are used in industrial and laboratory settings where large volumes of liquids need to be separated. Automatic separatory funnels are typically made of metal or plastic and are available in a variety of sizes.

Sizes of Separatory Funnel

Separatory funnels are available in different sizes ranging from 10 mL capacity to 5 L capacity. Common sizes include 25 mL, 50 mL, 100 mL, 250 mL, 500 mL, 1000 mL etc. The size is chosen based on the volumes of liquids to be separated. Bigger funnels are used to separate large volumes of liquids.

How to Use a Separatory Funnel

The steps to use a separatory funnel are:

- Clean and dry the separatory funnel thoroughly.

- Add the mixture of immiscible liquids into the funnel through the open end.

- Seal the open end of the funnel with a glass or cork stopper.

- Invert the funnel and vent any trapped air by slightly opening the stopcock.

- Return funnel to upright position allowing the liquids to settle into layers.

- Drain out the lower denser layer by carefully opening the stopcock.

- Drain out the upper lighter layer through the stopcock.

- Rinse the funnel with water or suitable solvent after separation.

Measurement

The volume of the immiscible liquids can be measured directly from the graduations on the separatory funnel body. For accurate measurement, the separatory funnel should be held vertically while draining out the liquids.

Experiments Using Separatory Funnel

Some common experiments and procedures done using a separatory funnel include:

- Separating mixtures of oil and water

- Extracting active ingredients from a mixture

- Purifying organic compounds from a reaction mixture

- Isolating plant pigments and dyes

- Phase transfer catalysis reactions

Uses of Separatory Funnel

The separatory funnel has various important uses in both chemical laboratories and industrial applications:

- Isolating desired compounds from a mixture

- Purifying compounds by separating from unwanted byproducts

- Separating corrosive acids and bases from reaction mixtures

- Extracting active medicinal compounds from plants

- Separating oil and water mixtures in petroleum industry

- Removing moisture from organic liquids

Also read:

Leave a Reply