Two Stroke Engine-Definition, Parts, Working, And Applications

The two stroke engine is a type of heat engine that is able to complete one energy cycle in just two strokes. The 4-stroke engine requires 4 strokes of the piston to complete the power/energy cycle within two turns of the crankshaft, but its working is the opposite of that.

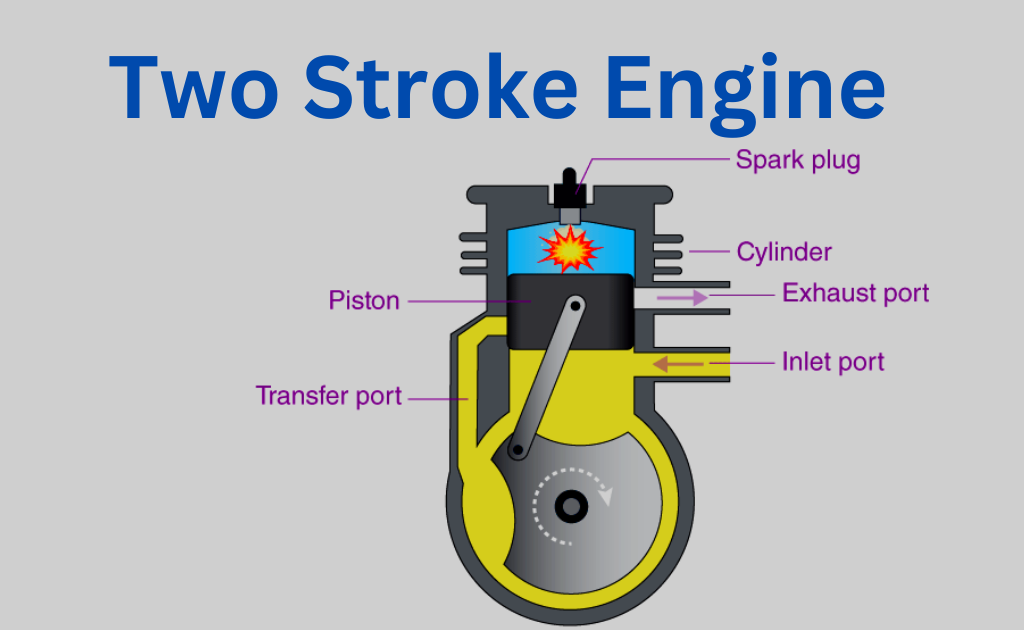

Two stroke engine

A two stroke cycle engine is an internal combustion engine that completes a power cycle in only two strokes, this cycle is completed in one revolution of the crankshaft.

A four-stroke engine requires four strokes of the pistons in order to complete a power cycle. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke occur at the same time. At the same time, both the intake and exhaust cycles happen.

Two-stroke engines are more efficient than four-stroke engines because they are less complicated to build and require fewer moving parts.

Generally, a 2-stroke petrol engine only converts 20% of the chemical (fuel) power into mechanical power. Only 15% of the total energy input to the engine is used to move the vehicle, while the remaining 85% goes to waste.

Parts of Two stroke Engine

These are some major parts of two stroke engine:

- Cylinder

- Cylinder head

- Piston

- Connecting rod

- Crankshaft

- Spark plug

Cylinder

The cylinder is constructed of cast iron of a 2-stroke engine. A cylinder is a very important part of an internal combustion engine. This cylinder is also called the combustion chamber.

Due to piston reciprocation, the air-fuel mixture compresses in the cylinder. It has inlet and outlet ports.

Cylinder Head

This part is located at the top of the engine’s cylinder. In the case of the gasoline engine, a cylinder head contains a spark plug. The two-stroke diesel engine has a fuel injector.

Piston

It is the main part of the cylinder. It is located inside the combustion chamber. It is made out of an aluminum alloy. The force of gases is transferred to the mechanical rotation of the crankshaft by the connecting rod.

Connecting Rods

This part of the engine is made of aluminum or steel alloy and absorbs light and strong forces. It links the crankshaft and the piston. One end of a crankshaft is attached to the piston and the other end is to the crankshaft.

It causes the motion of the piston to move toward the crankshaft.

Crankshaft

The crankshaft of the two stroke engine is made of cast iron forged steel. Diesel engines use steel crankshafts to help prevent stress from being put on the engine.

The crankshaft is used to change the vertical movement of the reciprocating piston into rotary motion.

Spark Plug

The objective of spark plugs is to ignite the fuel-air mixture. Spark plugs are only used on gas-fueled engines. It helps make the engine run smoother and last longer.

Working Principle of Two stroke Engine

The working of two stroke engine is completed in two-cycle.

1) Suction and Compression Stroke

Fresh air enters the combustion chamber when the piston moves from TDC to B DC. The fresh air-fuel mixture goes into the engine. In this stroke, the crankshaft makes a rotation.

Once the piston has pushed the mixture up through the valve, it moves back to the compression chamber, compressing the air-fuel mixture.

At the end of the compression stroke, the compressed mixture is ignited due to the spark provided by a spark plug.

2) Power and Exhaust Stroke

The power and exhaust strokes are the same as the compression and suction strokes. The temperature, internal heat, and pressure of the air-fuel mixture become very high when the combustion process is used.

The high-pressure gases produced during the combustion process exert a very high force on the piston due to the fact that it moves downward. The rotation of the vehicle’s flywheel can be accomplished by the downward motion of the crankshaft.

The exhaust valve is opened when the power is finished. The exhaust valve opens and the exhaust gases are pushed out of the chamber. The whole working cycle repeats when the piston reaches BDC, as it expels the exhaust gases and fills the combustion chamber with the fresh air-fuel mixture.

At BDC, one power stroke of the two-stroke engine is complete, and the next power cycle is just around the corner.

Applications of Two Stroke Engine

Two-stroke gasoline engines are preferred when mechanical simplicity, lightweight, and high power-to-weight ratio are priorities. They can operate in any orientation if they mix oil with fuel.

Two-stroke engines are used in a variety of applications, including outboard motors, small on- and off-road motorcycles, mopeds, scooters, tuk-tuks, snowmobiles, go-karts, ultralight, and model airplanes.

Handheld outdoor power tools such as leaf blowers, chainsaws, and string trimmers are great for working outside. Their high power-to-weight ratio and ability to be used in any orientation allow them to be used for a variety of jobs.

Large industrial and marine applications use two-stroke diesel engines, while some trucks and heavy machinery use two-stroke diesel engines.

Related FAQs

What is a two stroke engine called?

A two-stroke engine does the same things but in two different ways. The simplest two-stroke engines do this by using the underside of the moving piston as a fresh charge pump.

Why is a two stroke engine rarely used?

The problem of scavenging occurs in 2 stroke engines, which is why they are rarely used. The incomplete combustion of fuel and air mixture is referred to as scavenging. The fuel doesn’t get burnt out, it goes into the exhaust and doesn’t get into the fire.

Why is a 2-stroke engine so fast?

The two-stroke engine has a low number of parts than a four-stroke engine. It completes a working cycle in just 2 piston strokes instead of 4 strokes. Due to this reason, it is so fast.

Are 2-stroke engines more powerful?

A two-stroke engine has the highest Torque at low speeds, while a four-stroke engine has the highest Torque at high speeds. The 2-stroke engines are easy to operate and work quickly. It is more powerful because of this.

written by

written by

Leave a Reply