Types Of Spring-Based On Their Manufacturing And Shape

A mechanical spring is a piece of material with a very high yield strength that can be made elastic again. It serves as a shock absorber in many machines. Additionally, it prevents shocks and vibrations from being transferred to numerous important machine parts.

What Is Spring?

A spring is a material that may be bent by an external force before resuming its original shape. When a spring is squeezed, a force pushing each end apart has a magnitude proportional to the long drop from the equilibrium length.

A force pulling either end toward the other when a spring is extended has a magnitude proportional to the length increase from the equilibrium length.

Types Of Spring Based On Their Manufacturing

There are the following Types Of Spring Based On Their Manufacturing:

Coil Springs

Metal wires are formed into lightweight coil springs on a CNC coiling machine. The only restriction on the various pitches and end conditions users can generate with the multi-axis CNC control is their creativity.

The springy characteristics of the springs produced by coiling machines are limited. To develop from memory, they must first be heated to a high temperature (usually 500 degrees Fahrenheit or more) to relieve stress.

Flat Springs

Flat springs can be found in a wide variety of forms and sizes; some examples are spring washers, PCB spring contacts, and retainer clips. They are often composed of sheet metal and can be stamped. Coiled flat springs are also available; examples include clock and volute springs. Heat treatment is also required to form memory.

Machined Springs

For heavy-duty applications requiring high strength and precision, machined springs and die springs are preferred. Machined springs are produced on CNC lathes and mills, as the name implies.

Molded Springs

In corrosive settings including food processing, medical applications, and maritime applications, plastic or composite springs are typically used. They should only be utilized in intermittent cycles due to creep. They are more recent additions to the market than metal springs, therefore availability is not as abundant.

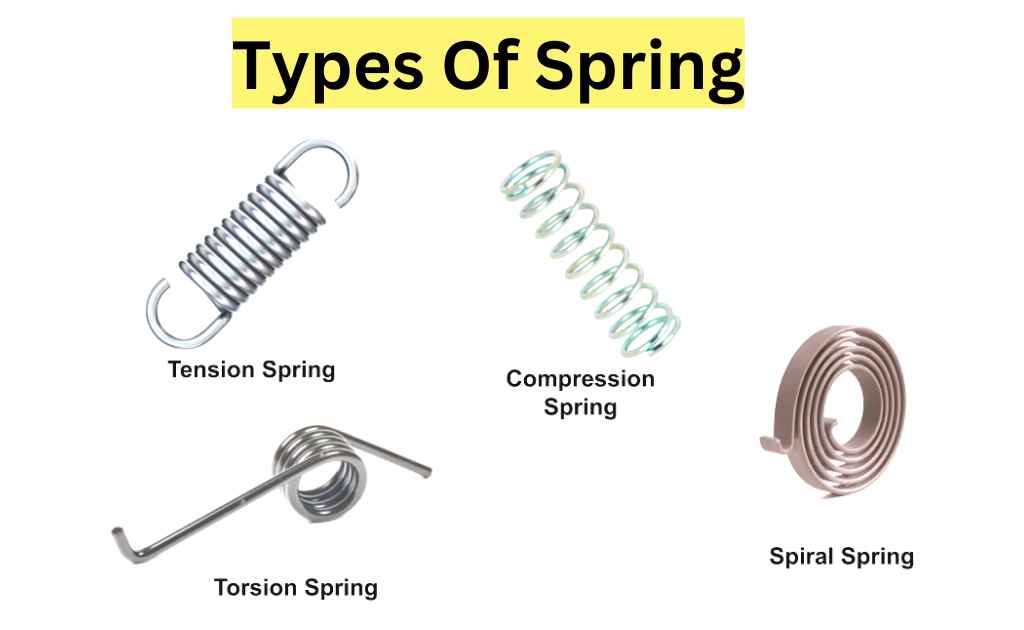

Types Of Springs Based On Their Shape

There are the following Types Of Springs Based On Their Shape:

Helical Spring

The most typical mechanical spring is the helical spring. A coil is wrapped in this kind of spring such that it resembles a thread. Helical springs are divided into the following four types based on the loading conditions.

Compression Springs

Open coil helical springs are called compression springs. A load presses or squeezes a helical coil. It resists push or compression pressures. The resistance to linear compressive pressures is also present. Fluids can occasionally act as fluid pressure systems or compression springs.

They are utilized in locks, pens, and suspensions for motorcycles.

Torsion Spring

The load placed on the coil of a torsion spring is a torque or twisting force. Torsion springs, in other terms, are helical springs that can store and release angular energy. These springs work to maintain a system.

The helical coil then twists and exerts force in the opposite way. In applications where the rotation is less than 360 degrees, tension springs are used. These springs can rotate either clockwise or counterclockwise.

They are utilized in clothing pins, rocker switches, and mouse traps.

Tension Springs

Extension Springs are another name for tension springs. The spring extends when a pull force is applied, causing it to do so. It is pull-resistant. These kinds of springs have extended or hook eyes on one or both ends.

They are utilized by vise-grip pliers and weighing machines. assemblies for garage doors

Spiral Springs

Clock springs and constant force springs are further names for spiral springs. To create these springs, a steel band was wrapped around them several times. These springs are employed in machinery that needs to rotate repeatedly while releasing the same amount of load continuously.

They release a constant amount of force. they are utilized in car seat recliners, alarm clocks, Regulators for watch windows, and DC Motor

written by

written by

Leave a Reply