Wedges Simple Machines-Introduction, Types, And Applications

Wedges Simple Machines have been used for centuries to accomplish various tasks. From splitting logs to cutting bone during surgery, wedges have a wide range of applications.

By understanding the principles of operation of wedges and their different applications, we can appreciate their importance and continue to use them safely and effectively.

What are Wedges Simple Machines?

Wedges are one of the simplest and oldest machines in human history, dating back to the Stone Age. The wedge simple machine has been used for centuries to accomplish various tasks that require force multiplication.

From construction and manufacturing to agriculture and medicine, wedges play a significant role in our daily lives. In this article, we’ll explore the different types of wedges, how they work, their applications, advantages and disadvantages, safety precautions when using them, and much more.

Types of Wedges

There are some types of wedges simple machines.

Inclined Plane

The inclined plane is the most common type of wedge. It is a flat surface that is tilted, allowing a load to be moved up or down with less force. It works by increasing the distance over which the force is applied, reducing the force required to move the load. Inclined planes are commonly used in ramps, stairs, and even roads.

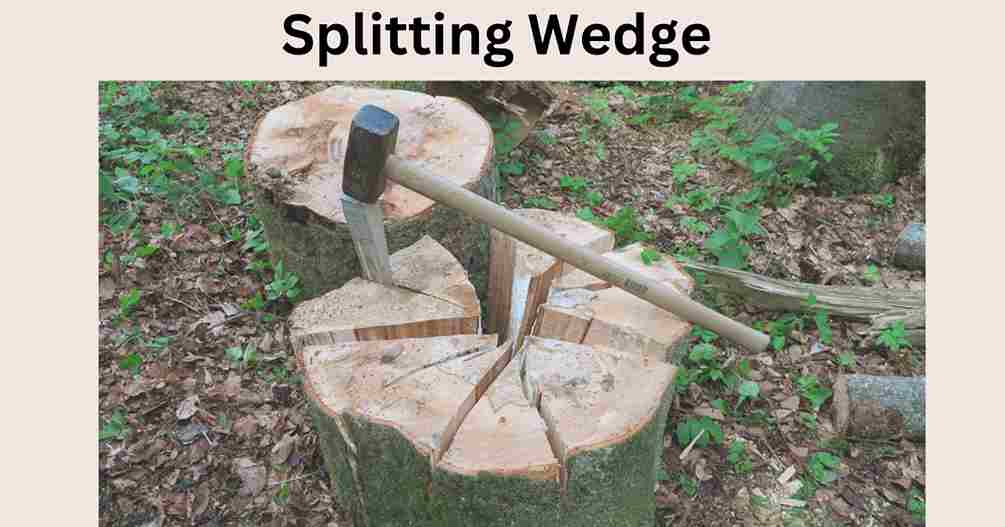

Splitting Wedge

Splitting wedges are used to split logs, stones, or other materials. They are thick and heavy, with a broad base that tapers to a sharp point. As the wedge is driven into the material, it forces it apart, creating a split. Splitting wedges are commonly used in forestry, construction, and manufacturing.

Chisel

A chisel is a tool that has a sharp, wedge-shaped blade at the end. It is used to cut or shape materials such as wood, metal, or stone. The chisel works by applying pressure to the material, causing it to fracture along a specific line.

Doorstop Wedge

A doorstop wedge is a small, triangular object used to hold doors open. It works by creating a wedge-shaped gap between the door and the floor, preventing it from closing. Doorstop wedges are commonly used in homes, offices, and other buildings.

How do Wedges Work?

Wedges work on the principle of increasing the distance over which force is applied. By doing this, the force required to move an object is reduced. This makes it easier to move heavy loads or cut through hard materials. When a wedge is driven into an object, the force applied to it is transferred to the material, causing it to split or move.

Applications of Wedges

Wedges are used in various applications across different fields. Some common applications of wedges include:

Construction

In construction, wedges are used to hold materials in place and provide support during the building process. For example, wooden shims can be used as wedges to level and secure building materials such as doors, windows, and framing.

Manufacturing

Wedges are also used in manufacturing to cut or shape materials such as metal, plastic, or wood. For example, a chisel is a type of wedge that is used to cut through materials like stone or metal.

Agriculture

In agriculture, wedges are used to harvest crops, split logs, and trim animal hooves and teeth. For example, an axe is a type of wedge that is used to chop down trees and split logs, while a hoof trimmer is a type of wedge that is used to trim animal hooves.

Medicine

Wedges are also used in medicine for cutting bone and tissue during surgical procedures. They are also used to spread or hold tissues in place during surgery.

Advantages of Wedges Simple Machines

Wedges Simple Machines have several advantages that make them useful in various applications. Some of the benefits of wedges include:

Force multiplication: Wedges can multiply the force applied to them, making it easier to move heavy loads or cut through hard materials.

Simple design: Wedges have a simple design that makes them easy to manufacture and use.

Versatility: Wedges can be used in various applications, from construction and manufacturing to medicine and agriculture.

Disadvantages of Wedges Simple Machines

Wedges also have some disadvantages that should be considered. Some of the drawbacks of wedges include:

Safety concerns: Wedges can be dangerous if not used properly, and users need to take proper safety precautions.

Limited range of motion: Wedges can only move in a straight line, making them unsuitable for some applications.

Limited effectiveness: Wedges may not be effective in some situations, such as when dealing with materials that are too hard or dense.

Safety Precautions for Using Wedges

When using wedges, it’s essential to take proper safety precautions to avoid accidents and injuries. Some general safety tips include:

- Always wear protective gear, such as gloves, goggles, and a hard hat.

- Make sure the wedge is sharp and in good condition before using it.

- Use the wedge only for its intended purpose and avoid using it in ways that can cause damage or injury.

- Make sure the material you are working with is stable and secure before using the wedge.

- Keep your hands and other body parts away from the wedge’s sharp edges.

Specific precautions for different types of wedges may include:

Splitting wedges: Always make sure the log or material being split is stable and won’t roll or move while you’re working on it. Use a wedge that is appropriate for the size and density of the material you’re splitting.

Chisels: Always hold the chisel with both hands and use a mallet or hammer to strike it. Avoid using excessive force, as this can cause the chisel to slip or break.

Doorstop wedges: Always make sure the door is stable and won’t move while the wedge is in place. Avoid using the wedge on doors that are too heavy or have a large gap.

written by

written by

Leave a Reply