What is Ammeter?- Function, Specifications, and Temperature Effects

What is an Ammeter?

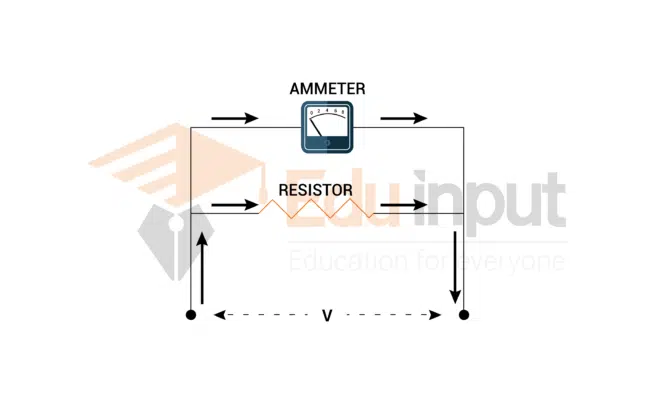

An ammeter is an instrument used to measure electric current(AC and DC) in a circuit. It is designed to be connected in series with the circuit allowing the current to pass through it. Ammeters enable users to monitor and analyze electrical currents in various applications by providing accurate readings.

Ammeters play a vital role in measuring electric current. They provide valuable information about the flow of electric charge through a conductor.

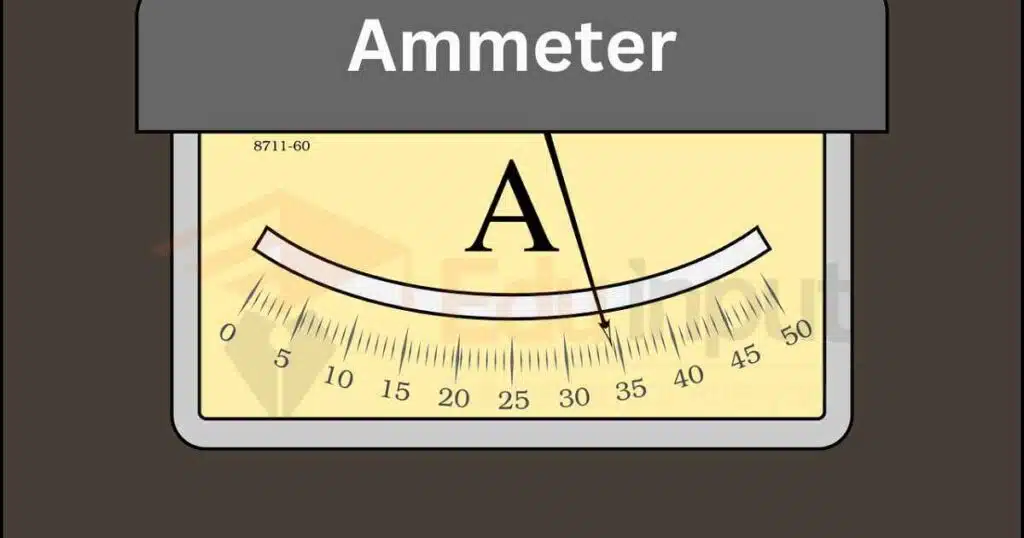

Representation of an Ammeter

An ammeter is represented by a circular dial with a needle that points to a scale marked in amperes (A). The scale may be calibrated in milliamperes (mA) for smaller currents or kiloamperes (kA) for larger currents, depending on the range of the ammeter. The dial also includes markings indicating zero current and various current values.

Ammeter Specifications

It is essential to consider ammeter specifications to ensure it meets the specific requirements of the application. Here are some common specifications to consider:

- Current Range: Ammeters are available in different current ranges, allowing users to measure currents from milliamperes to kiloamperes. Choosing the appropriate range ensures accurate readings and prevents damage to the instrument.

- Accuracy: The accuracy of an ammeter refers to its ability to provide measurements close to the actual current value. Higher accuracy is desirable for precise measurements, especially in critical applications.

- Sensitivity: Sensitivity determines the smallest current that an ammeter can measure accurately. A highly sensitive ammeter can measure low currents, while a less sensitive one requires higher currents for accurate readings.

- Overload Protection: To safeguard the ammeter from excessive currents, many models feature overload protection mechanisms such as fuses or circuit breakers. These protect the instrument and prevent damage.

Classification of Ammeters

Ammeters can be classified into two main types:

Analog Ammeters

Analog ammeters employ a moving coil mechanism, where the electric current generates a magnetic field that moves the coil and deflects the needle on the dial. They provide continuous readings and are known for their simplicity and reliability.

Digital Ammeters

Digital ammeters use electronic circuits to measure and display the current digitally. They offer greater precision and multiple reading options. It often includes additional features such as data logging and communication interfaces.

Effect of Temperature on Ammeters

Temperature can have a significant impact on the performance and accuracy of ammeters. Here are a few key effects:

- Thermal Expansion: Analog Ammeters may experience changes in their internal components due to thermal expansion. This expansion can cause slight variations in readings, leading to measurement errors.

- Temperature Coefficient: Some ammeters have a temperature coefficient that describes how their accuracy changes with temperature. It is crucial to consider this coefficient when using ammeters in environments with varying temperatures.

- Calibration: Fluctuations in temperature can affect the calibration of ammeters. Calibration ensures accurate readings, and changes in temperature may require periodic recalibration to maintain measurement precision.

Uses of Ammeters

Ammeters find widespread application in various industries and settings where the measurement of electric current is crucial. Here are some of the common uses of ammeters:

- Circuit Analysis: Ammeters are extensively used in circuit analysis to measure the current flowing through different components and sections of a circuit. By measuring current values, engineers and technicians can identify potential issues, ensure proper functioning, and optimize the performance of electrical systems.

- Electrical Testing and Troubleshooting: Ammeters are valuable tools for electrical testing and troubleshooting. They help identify faulty components or connections by measuring the current at different points in a circuit. By comparing expected and actual current values, technicians can pinpoint the source of electrical problems and take corrective actions.

- Electrical Maintenance and Safety: In industrial and commercial settings, regular electrical maintenance is crucial to prevent accidents and ensure the safe operation of equipment. Ammeters are used during maintenance procedures to verify that current values are within acceptable limits, detect abnormal currents, and assess the condition of electrical systems.

- Energy Monitoring: Ammeters play a vital role in energy monitoring and management. By measuring the current consumed by individual devices or sections of a power distribution network, energy consumption can be analyzed and optimized. This information helps identify energy-saving opportunities, improve efficiency, and reduce costs.

- Electric Vehicle Charging: Ammeters are essential components of electric vehicle (EV) charging stations. They measure the current drawn by the EV during charging, allowing users to monitor the charging process and ensure safe and efficient operation. Ammeters help prevent the overloading of charging circuits and provide real-time feedback on the charging status.

- Laboratory Experiments and Research: In educational institutions and research laboratories, ammeters are used in various experiments to study electrical phenomena, analyze circuit behavior, and verify theoretical models. They allow students and researchers to observe and measure current flow, enabling a deeper understanding of electrical principles.

- Renewable Energy Systems: Ammeters are employed in renewable energy systems, such as solar panels and wind turbines, to monitor and optimize the current flow. They help assess the performance of these systems, track energy generation, and ensure efficient utilization of renewable resources.

- Industrial Control Systems: Ammeters play a critical role in industrial control systems, where accurate measurement of current is essential for monitoring and controlling processes. They enable operators to monitor the current draw of motors, pumps, and other electrical devices, ensuring proper operation and identifying any abnormalities.

Leave a Reply