Elastic limit and Yield Strength

The difference between elastic limit and yield strength is the Elastic limit is the maximum stress that a material can withstand before permanent deformation. The point at which the material transforms from elastic to plastic is known as the yield point.

Difference between Elastic limit and yield strength

Elastic limit and yield strength can be explained by the tensile test.

Tensile Test

In a tensile test, the material wire is extended at a uniform deformation rate. The stress generated during the deformation is continuously monitored by electronic devices, which are fitted within the mechanical testing machine.

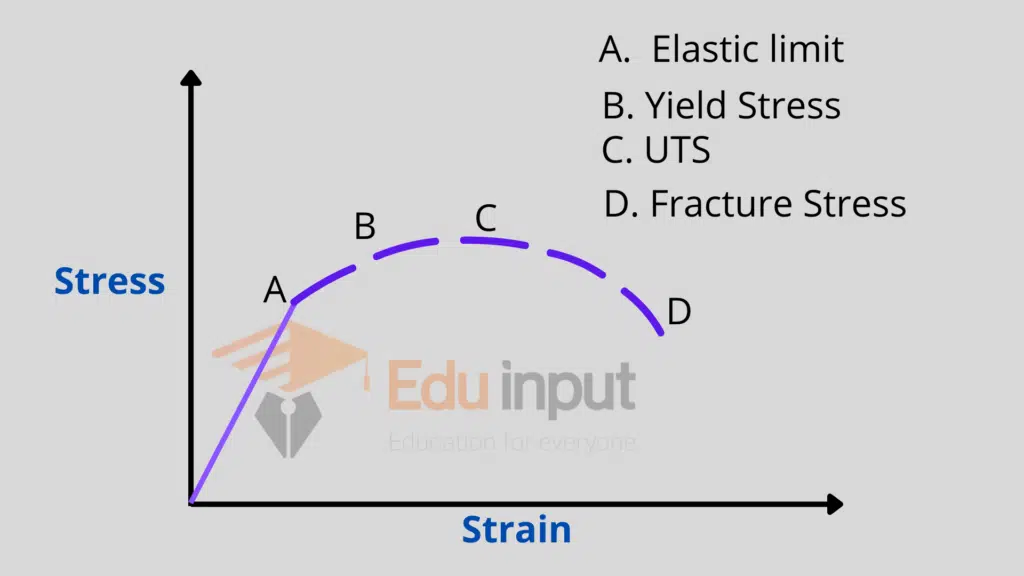

A stress-strain curve is automatically plotted on an x-y chart recorder. This is a typical stress-strain curve for a ductile material.

In the initial stages, the stress is increased linearly with the strain till point A on the curve. The straight line also indicates the linear behavior between the stress and produced strain. This is called the proportional limit (σp).

Proportional limit of stress and strain

The greatest stress that a material can endure without losing straight line proportionality between stress and strain. For all practical purposes, the proportional limit (σp) can be considered identical to the elastic limit.

What is an Elastic limit?

The greatest stress that a material can bear without any permanent change in shape or dimensions.

Hook’s law is applicable in this region. Deformation produced in this region is temporary and after removing the applied stress the body returns to its original state. This temporary deformation is called elastic deformation.

What is Yield stress?

The maximum value of applied stress within its elastic limit is called yield stress.

What is Plasticity?

If the stress is increased beyond the elastic limit, the specimen becomes permanently changed and does not regain its original state even if the applied stress is removed. This is called plasticity.

Ultimate tensile stress (UTS):

The maximum stress that a material can withstand”, and can be regarded as the nominal strength of the material or Ultimate tensile stress (UTS)( σm).

Fracture stress

Once UTS is crossed, the material breaks at this point and is called fracture stress (σf).

Ductile Substances:

Substances that undergo plastic deformation until they break are known as ductile substances. Lead, copper, and wrought iron are ductile.

Brittle Substances:

Substances that break just after the elastic limit is reached are known as brittle substances. Glass and high-carbon steel are brittle.

Related FAQs

What’s the difference between elastic limit and yield point?

The elastic limit is the point till which the wire retains its original length after the force is withdrawn. The yield point is the point where there is a large permanent change in length with no extra load force.

What is the difference between elastic limit and ultimate strength?

Yield strength indicates the maximum stress or load that a solid material can withstand when it is deformed within its elastic limit. On the other hand, ultimate strength indicates the maximum stress or load-withstanding capability of a material when it is plastically deformed.

What is the elastic limit means?

The elastic limit is the maximum stress a material can withstand before permanent deformation. It is the material’s highest limit before the material’s plastic deformation can occur. Once the stress or force is removed from the material, the material comes back to its original shape.

What is the elastic limit in the strength of materials?

The elastic limit of a material is the maximum stress that can be developed within it without causing permanent deformation or permanent stretch, in oil-field terms.

Leave a Reply