Electrostatic Precipitator-Definition, Working, And Uses

An electrostatic precipitator (ESP) is a device that removes particles from a gas stream by utilizing electrical energy to electric charge the particles either positively or negatively. These charged particles are then drawn toward collector plates that carry the opposite charge.

What is an Electrostatic Precipitator?

An electrostatic precipitator is an advanced air pollution control device designed to remove fine particulate matter (PM) such as dust, smoke, and ash from industrial and power plant emissions. It operates on the principle of electrostatic attraction and uses electrical charges to capture and collect the particles.

The working principle of ESPs revolves around the electrostatic attraction and removal of particles. By applying a high voltage to the collection plates, the negatively charged particles are drawn towards them, allowing for efficient separation from the air stream.

One prominent example of an ESP application is its use in coal-fired power plants. These power plants generate large quantities of fly ash, which contains fine particles and harmful pollutants. ESPs efficiently capture and remove these particles, significantly reducing emissions and improving air quality.

ESPs typically operate using DC (direct current) power supplies. The DC voltage creates an electric field between the collection plates and the discharge electrodes, facilitating the particle collection process.

Who Uses Electrostatic Precipitators?

ESPs are widely used in various industries and power plants. Industries such as cement, steel, chemical, pulp and paper, and coal-fired power plants often employ ESPs to meet stringent air quality regulations. Waste incinerators and biomass plants utilize electrostatic precipitators to control the emission of pollutants.

How do Electrostatic Precipitators Remove Pollutants?

ESPs remove pollutants through a series of steps:

Ionization

When polluted air enters the Electrostatic Precipitator (ESP), it goes through an ionization section. In this section, high-voltage electrodes produce a corona discharge. This discharge charges the particles in the air, creating negative and positive ions.

Collection

The charged particles are then attracted to oppositely charged collection plates or tubes. These plates act as a barrier, causing the particles to migrate and adhere to the surface, effectively removing them from the air stream.

Cleaning

Over time, the particles that accumulate on the plates of the capacitor form a layer. To ensure the capacitor functions at its best, a cleaning mechanism is used to remove these particles. This can be done through methods like rapping or mechanical vibrations, which shake the plates and dislodge the particles.

Once dislodged, the particles fall into designated hoppers for proper disposal. This cleaning process helps maintain the optimal efficiency of the capacitor by preventing the buildup of unwanted particles on its plates.

What Pollutants Do Electrostatic Precipitators Remove?

ESP are highly effective at removing various pollutants including:

- Fly ash and dust particles are generated by industrial processes and power plants.

- Fine particulate matter (PM2.5 and PM10) originates from combustion processes, including smoke and soot.

- Sulfur dioxide (SO2) and nitrogen oxides (NOx) are emitted by coal-fired power plants and industrial boilers.

- Heavy metals and metal compounds are released during metal smelting and other industrial operations.

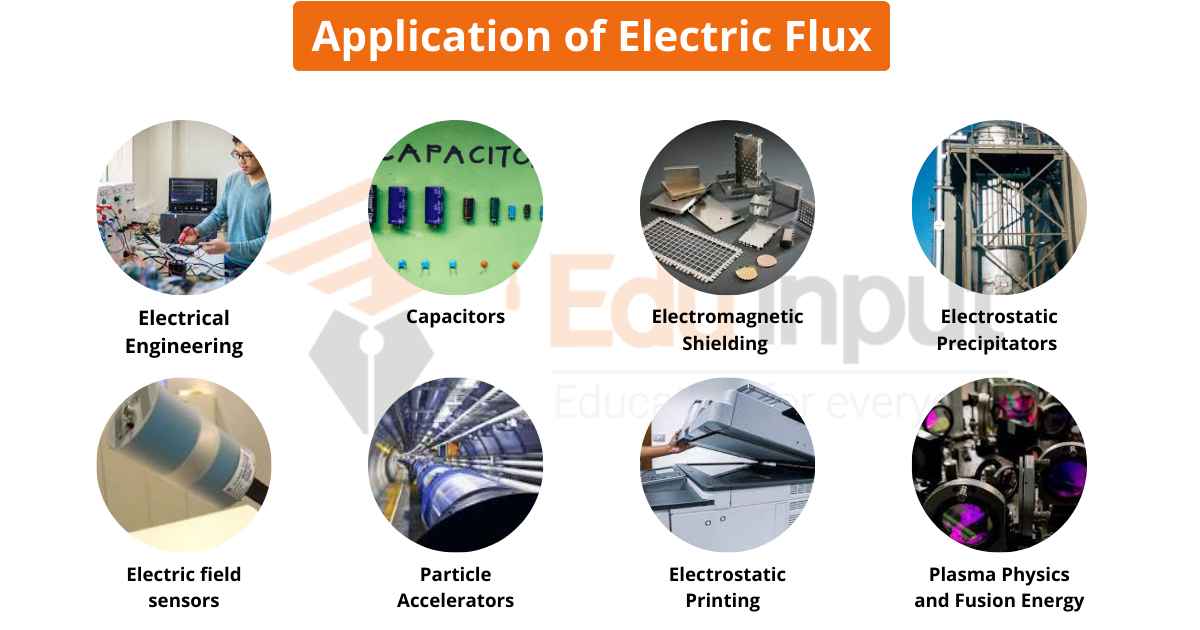

Uses of Electrostatic Precipitators

Electrostatic precipitators find diverse applications in different industries, including:

Power Generation: ESPs are widely utilized in thermal power plants to control emissions of fly ash, sulfur dioxide, and other pollutants produced during coal combustion.

Industrial Processes: Industries such as cement, steel, and chemical manufacturing employ electrostatic precipitators to control the release of particulate matter, dust, and various pollutants generated during their manufacturing processes.

Waste Incineration: Electrostatic precipitators are essential in waste incineration plants to capture and remove harmful emissions, including fly ash, heavy metals, and dioxins produced during the combustion of waste materials.

Pulp and Paper Industry: ESPs are used in pulp and paper mills to control emissions of particulate matter, sulfur compounds, and other pollutants released during various production stages, such as wood processing and chemical pulping.

Metal Smelting: Electrostatic precipitators are employed in metal smelting facilities to reduce the release of particulates and metal compounds, ensuring compliance with environmental regulations and improving air quality in surrounding areas.

Chemical and Petrochemical Plants: These industries rely on electrostatic precipitators to capture and remove fine particles, fumes, and volatile organic compounds (VOCs) produced during chemical reactions, distillation, and refining processes.

Pharmaceutical Manufacturing: ESPs play a crucial role in pharmaceutical plants by effectively controlling emissions of airborne particles, dust, and contaminants generated during drug manufacturing and packaging processes.

Cement and Construction Materials: Electrostatic precipitators are utilized in cement plants and construction material manufacturing facilities to control emissions of particulate matter, cement dust, and other pollutants arising from grinding, kiln operations, and material handling.

Air Pollution Control Systems: Electrostatic precipitators are often integrated into larger air pollution control systems, working in conjunction with other technologies such as fabric filters and scrubbers, to provide comprehensive pollution mitigation in diverse industries.

Related FAQs

What is an electrostatic precipitator also called?

An electrostatic precipitator is also called an air-cleaning device that uses electricity to remove impurities from gases and smokestacks, keeping the air cleaner and reducing pollution.

Is electrostatic precipitator AC or DC?

An electrostatic precipitator typically operates using DC (direct current) power.

What is the voltage of an electrostatic precipitator?

The voltage of an ESP can vary depending on the specific design and application, but it typically ranges from a few thousand to tens of thousands of volts.

Leave a Reply