Crystallization-Principle, types, process, applications

Crystallization is the removal of a solid from solution by increasing its concentration above the saturation point in such a manner that the excess solid separates out in the form of crystals.

Objective

The primary use of crystallization is as a separation process to separate pure crystals of a chemical from an impure mixture. The process of crystallization is used to extract pure salt from seawater, which is another significant use. To create pure alum crystals from impure alum, crystallization can also be used.

We can say that the preparation of a chemical compound usually affords a crude product and there is a need to purify it by crystallization from a suitable solvent.

Principle

The basic principle of crystallization is the fact that the solute should be soluble in a suitable solvent at high temperature and the excess amount of the solute is obtained in the form of crystals when it is cooled.

Types of Crystallization:

There are two main types of crystallization: cooling crystallization and evaporation crystallization. Cooling crystallization is used when the solubility of the solute decreases with decreasing temperature. Evaporation crystallization, on the other hand, is used when the solute is more soluble in the solvent at higher temperatures.

Cooling Crystallization:

Cooling crystallization involves cooling a saturated solution of the solute until it becomes supersaturated. The supersaturated solution is unstable, and any disturbance, such as scratching the inside of the container or adding a seed crystal, can cause the solute to crystallize. The crystal structure and size are determined by factors such as temperature, cooling rate, and stirring.

Evaporation Crystallization:

Evaporation crystallization involves evaporating the solvent from a solution until it becomes supersaturated. As the solvent evaporates, the concentration of the solute increases until it reaches a point where it is no longer soluble. The solute then crystallizes out of the solution. The crystal structure and size are determined by factors such as the rate of evaporation and the degree of supersaturation.

Process of crystallization

The process of crystallization involves the following steps.

Choice of solvent

The solvent is chosen on hit and trial basis and it is necessary to try a number of solvents before arriving at a conclusion. An ideal solvent should have the following features.

It should dissolve a large amount of the substance at its boiling point and only a small amount at room temperature.

It should not react chemically with the solute.

It should either not dissolve the impurities or impurities should not crystallize from it along with the solute.

On cooling, it should deposit well-formed crystals of the pure compound.

It should be inexpensive.

It should be safe to use and should be easily removable.

Commonly Used Solvents

The solvents which are mostly used for crystallization are water, rectified spirit, absolute ethanol, diethyl ether, chloroform, acetone, carbon tetrachloride, acetic acid, and petroleum ether.

Use of Combination of Solvents

If none of the solvents is found suitable for crystallization, a combination of two or more miscible solvents may be employed.

Care of Inflammable Solvents

If the solvent is inflammable then precaution should be taken while heating the solution so that it does not catch fire. In such cases, the water bath is used for heating purposes.

Preparation of the saturated solution

After selecting a suitable solvent, the substance is then dissolved in a minimum amount of solvent is heated directly or on a water bath with constant stirring.

Add more solvent to the boiling solution if necessary until all the solute has dissolved.

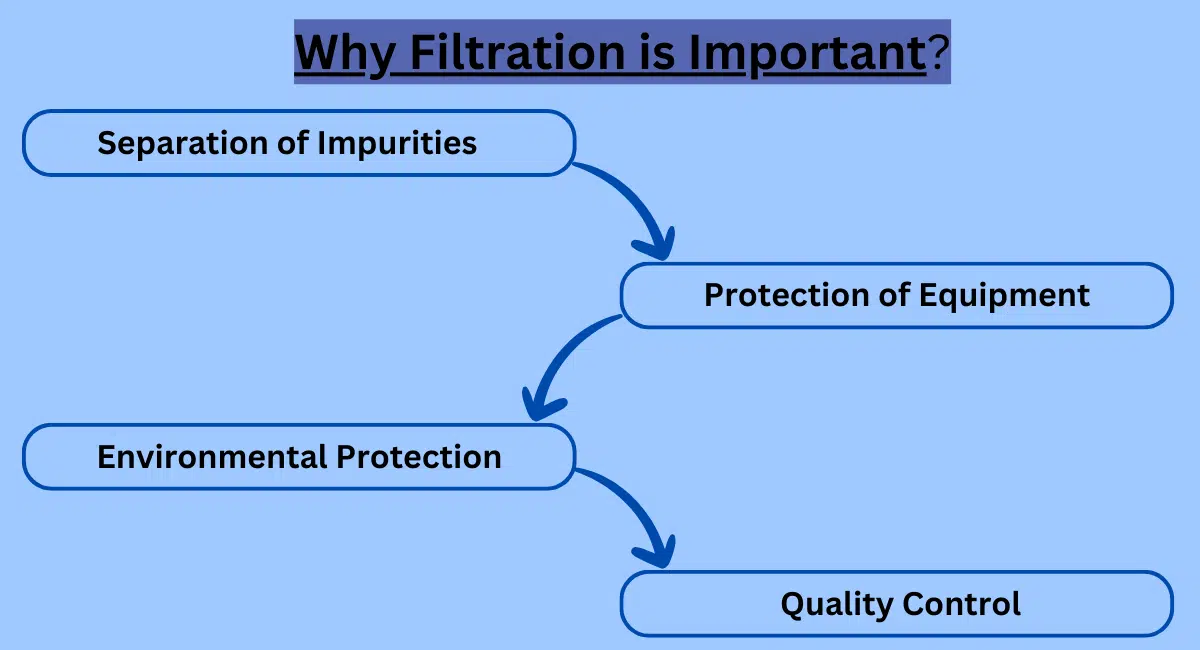

Filtration

The insoluble impurities in the saturated solution are then removed by filtering the hot saturated solution, through a normal or a fluted filter paper. It is done through the filtration process.

This avoids the premature crystallization of the solute on the filter paper or in the funnel stem.

Precaution

If the solvent is inflammable, there should be no direct heating. A hot water funnel should be used to avoid catching fire.

Cooling

Moderate Cooling: The hot filtered solution is then cooled at a moderate rate so that medium-sized crystals are formed.

Slow Cooling: Slow cooling yields bigger crystals which are likely to include a considerable amount of solvent carrying impurities with it and complicating the drying process.

Fast Cooling: Fast cooling yields small-sized crystals.

Collecting the crystals

Filtration

When the crystallization is complete, the mixture of crystals and the mother liquor is filtered through a Gooch crucible using a vacuum pump.

Full suction is applied in order to drain the mother liquor from the crystals as effectively as possible.

Pressing

When the filter cake is rigid enough, it is pressed firmly with a cork to drain the leftover liquid.

Washing

The crystals are then washed with a small portion of cold solvent and the process is repeated several times.

Evaporation

The mother liquor is quite often concentrated by evaporation and cooled to obtain a fresh crop of crystals.

Drying of the crystallized substance

Through Filter Paper

Pressing it between several folds of filter papers and repeating the process several times dries the crystallized substance.

This process has the disadvantage that the crystals are crushed to a fine powder and sometimes the fibers of filter paper contaminate the product.

Drying in an Oven

Alternatively, the crystals are dried in an oven, provided, the substance does not melt or decompose on heating at 100.

Vacuum Desiccators

A safe and reliable method of drying crystals is through vacuum desiccators.

In this process, the crystals are spread over a watch glass and kept in vacuum desiccators for several hours.

Drying agents used in desiccators are

CaCl2, silica gel, or phosphorus pentoxide.

Decolorization of undesirable colors

Sometimes during the preparation of a crude substance, the coloring matter or resinous products affect the appearance of the product and it may appear colored.

Such impurities are conveniently removed by boiling the substance in the solvent with a sufficient quantity of finely powdered animal charcoal and then filtering the hot solution.

The colored impurities are absorbed by animal charcoal and the pure decolorized substance crystallizes out from the filtrate on cooling.

Applications of Crystallization:

Crystallization is used in various industries for the production of high-purity materials. For example, the pharmaceutical industry uses crystallization to purify drugs and separate stereoisomers. The chemical industry uses crystallization to purify chemicals and separate isomers. The food industry uses crystallization to produce high-quality sugar and salt.

Also Read:

What is crystallization in simple words?

Crystallization refers to the solidification of a liquid substance into a highly structured solid whose atoms or molecules are placed in a well-defined three-dimensional crystal lattice.

What are the 5 steps of crystallization?

There are five major steps in the recrystallization process: dissolving the solute in the solvent, performing a gravity filtration, if necessary, obtaining crystals of the solute, collecting the solute crystals by vacuum filtration, and, finally, drying the resulting crystals.

How is crystallization formed?

Crystallization is based on the principles of solubility: compounds (solutes) tend to be more soluble in hot liquids (solvents) than they are in cold liquids. If a saturated hot solution is allowed to cool, the solute is no longer soluble in the solvent and forms crystals of pure compound.

What is the crystallization of water?

The water of crystallization is the number of water molecules that combine chemically in definite molecular proportion, with the concerned salt in the crystalline state. This water is responsible for the geometric shape and color of the crystals. Suggest Corrections.

What are the two types of crystallization?

The most frequently applied types of crystallization are Evaporative crystallization. Cooling crystallization from solution or the melt.

Is crystalline solid or liquid?

A crystal or crystalline solid is a solid material whose constituents (such as atoms, molecules, or ions) are arranged in a highly ordered microscopic structure, forming a crystal lattice that extends in all directions.

What are the factors of crystallization?

The crystallization process is affected by the physical conditions of the solution, solution solubility, the presence of impurities, nucleation, solution saturation and degree of supersaturation, and crystal growth, including solution composition, pH, and temperature, and to date is not fully understood.

Leave a Reply