Galvanometer-Definition, Working, and Construction

The Galvanometer is defined as An electrical instrument used to detect the passage of current or comparison of current is called a Galvanometer.

Working Principle of Galvanometer

The working principle of the galvanometer depends upon the fact that when a conductor is placed in a magnetic field, it experiences a force. Due to this force, a torque rotates it indicating the flow of electric current.

Construction of Galvanometer

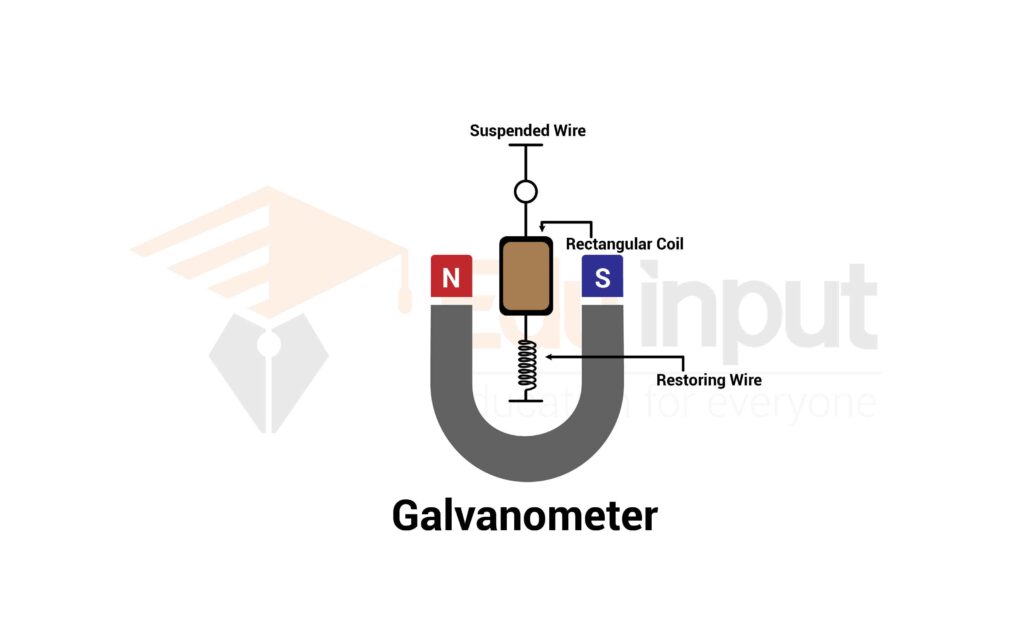

It consists of a rectangular coil C which is suspended between two concave-shaped poles N and S of a U-shaped magnet with the help of a fine metallic suspension wire. The rectangular coil is made of enameled copper wire. The wire is wound on a rectangular frame of some non-magnetic material.

The suspension wire F also acts as one current lead to the coil. The other terminal of the coil is connected to a loosely wound spiral E which acts as a second current lead.

Deflecting Couple

When I current passes through the coil, the coil is acted upon by a couple which tends to rotate the coil. This couple is known as deflecting couple and is given by

Deflecting couple =NIBA cosα

As the magnetic field is radial and in a radial magnetic field the plane of the coil is always parallel to the field. So α Is always zero.

Deflecting couple=NIBA cos0=NIBA

Restoring Torque

When the coil turns under the action of deflecting couple, a restoring couple is produced which tends to untwist the suspension wire and restores the coil to its original position.

This restoring couple of the suspension wire is proportional to the angle of deflection θ as long as the suspension wire obeys Hooke’s law,

Restoring torque = Cθ

Where C is called Torsional Couple of suspension wire and is defined as a couple per unit twist. When the coil is in equilibrium then deflecting torque is equal to restoring torque.

Deflecting torque=Restoring torque

NIAB=Cθ

I=(C/BAN) θ

I∝ θ

Thus the current passing through the coil is directly proportional to the angle of deflection.

Measurement of angle of deflection in the galvanometer

There are two methods used for measuring the angle of deflection:

Lamp and Scale Arrangement

In a sensitive galvanometer, the angle of deflection is measured using a small mirror attached to the coil along with a lamp and scale arrangement.

A beam of light from the lamp is directed towards the mirror of the galvanometer.

After reflection from the mirror, it produces a spot on a translucent scale placed at a distance of one meter from the galvanometer.

When current passes through the coil, the coil rotates the mirror also rotates, and the spot of light moves along the scale. The displacement of the light spot on the scale is proportional to the angle of deflection provided θ is small.

Weston Type Galvanometer

In such type, the coil is pivoted between two jeweled bearings. The restoring torque is provided by two hairsprings which also act as current leads.

A light aluminum pointer is attached to the coil which moves over the scale. It gives the angle of deflection of the coil.

Sensitivity of Galvanometer

A galvanometer is said to be sensitive if it gives a large deflection for a very small current.

As I=C θ /NAB the galvanometer can be made more sensitive if C θ /NAB is made small, for a given current I,θ should be maximum.

It can be done by increasing the length of the suspension wire and by decreasing its diameter. But practically it is not possible because the suspension wire must be strong enough to support the coil.

The area and number of turns cannot be increased beyond a limit because it will make the coil heavy.

It can be done by using a magnet having a strong magnetic field strength ‘B’, to increase the sensitivity of the

Current sensitivity

We define the current sensitivity of a galvanometer as the current in microamperes required to produce one-millimeter deflection on a scale placed one meter away from the mirror of the galvanometer.

Unstable Galvanometer

When the current passing through the Galvanometer is stopped suddenly, the coil will not come to rest. It keeps on oscillating about its mean position before coming to rest.

Similarly, if the current is suddenly given to the galvanometer, the coil will shoot beyond its fixed equilibrium position and will oscillate several times before coming to rest.

Such a galvanometer is called an Unstable Galvanometer Artificial methods are used to make the coil come to rest quickly.

Stable or deadbeat galvanometer:

A galvanometer in which a coil comes to rest quickly after the current is passed through it or the current flowing through it is called a stable or dead galvanometer.

Leave a Reply