What is Friction | Methods for Reduction of friction

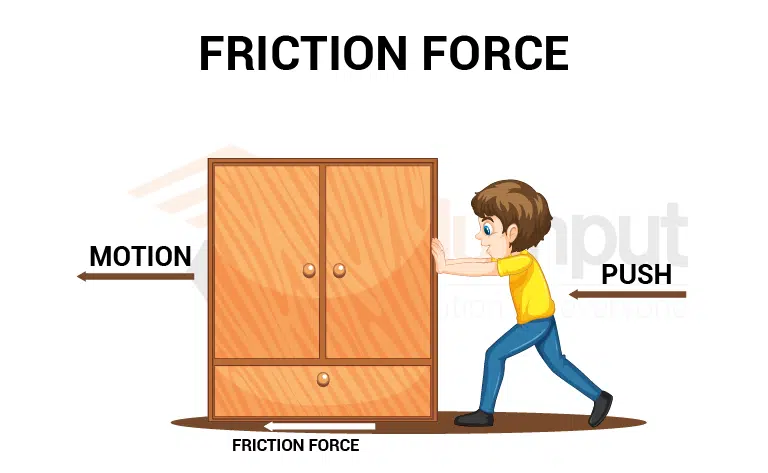

Friction is the phenomenon of opposing forces due to which we experience a slow motion(linear motion or circular motion). When two objects are in contact with each other, then one of them is going to move and the other one is not. So, if there is no friction, then the movement will be continuous.

What is Friction?

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. The force resisting the motion of a fluid across the surface of a body is called drag and is a component of lubricated friction. When surfaces in contact move relative to each other, the force resisting motion between the elements creates thermal energy and converts it to work.

The use of rubbing wood pieces together to start a fire is an example of how this property can have dramatic consequences. When a fluid is stirred, the thermal energy of the fluid is converted to Kinetic energy. Performance degradation or damage to components can be caused by wear, which is an important consequence of many types of friction. The science of tribology has a component called Friction.

It’s important that traction is supplied in order to facilitate movement on the land. The majority of land vehicles rely on friction to accelerate, decelerate and change direction. The loss of control and accidents can be caused by a sudden reduction in traction.

There isn’t a fundamental force that Friction is. There is a combination of inter-surface adhesion, surface roughness, surface deformation, and surface contamination. The use of empirical methods for analysis and the development of theory is necessary because of the complexity of these interactions.

Friction is not a conservative force and work done against it is dependent on the path. The mechanical energy is not conserved because it is transformed into thermal energy in the presence of friction.

Types of friction

There are different types of friction

Dry friction

Dry friction is resistant to the motion of two solid surfaces in close proximity. There are two regimes of dry friction, one between moving and non-moving surfaces, and the other between moving and non-moving surfaces.

Static friction

There are two or more solid objects that are not moving relative to one another. It is possible to prevent an object from sliding down a sloped surface with the use of static friction. The coefficient of static friction is usually higher than the coefficients of kinetic friction.

Kinetic friction

When two objects are moving relative to each other and rubbing together, it’s called sliding friction or kinetic friction. The kinetic friction is typically denoted as μk and less than the coefficient of static friction for the same materials

Coefficient of friction

The ratio of the frictional force resisting the motion of two surfaces in contact to the normal force pressing the two surfaces together is called the coefficient of friction. It is usually represented by the Greek letter mu. When F is the normal force and N is the frictional force, is the equation. Mathematically, μ = F/N

Methods for Reduction of friction

The surfaces should be made a little bit more smooth. Making the surface smooth will increase the number of bonds that will form on the surface. It is possible to make a surface more smooth by lubricating it. The object can be made more streamlined with the help of a slippery substance. The least resistance is offered by a streamlined shape, one that allows air or water to flow around it easily.

The surface in contact with the Normal force should be reduced. The higher the Normal force acting on the surfaces is, the higher the friction. There will be less number of bonds formed if the contact between the surfaces is reduced. Very little of a spherical object is in contact with the other surface, and that’s why Spheres are the best shape for reducing friction.

Devices such as wheels, ball bearings, roller bearings, air cushions, or other types of fluid bearings can change sliding friction into a much smaller type. A number of materials are used in low-friction bearings. For improved wear resistance, very high molecular weight grades are usually specified for critical bearings.

Leave a Reply